1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

Various filter ‘vacuum pre-treatment type’ ultrasonic cleaning systems.

Eliminate the misconceptions of ultrasonic cleaning and introduce true ultrasonic cleaning technology to the world of filter cleaning!

Introducing true ultrasonic cleaning technology to the filter cleaning world!

- Blue Star R&D’s extraordinary capabilities for filter cleaning

Disc filters and pleated filters for LCD films, turbine air intake HEPA filters for thermal power stations, general purpose filters for factory offices, oil filtration filters for ships…., etc.If you need help with cleaning filters, please contact us.

Filters used for filtration, which are a complex combination of metal, synthetic fibres and non-woven fabrics, are one of the most difficult objects to clean, regardless of their material or pore size.

However, Blue Star R&D offers a superior cleaning system based on correct ultrasonic cleaning theory that is easy for customers to understand.

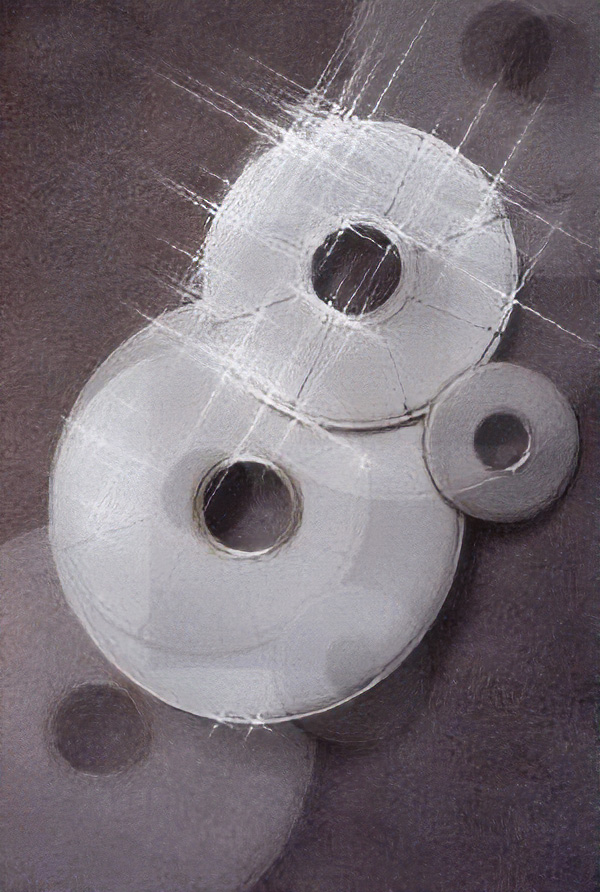

Example of a liquid crystal and fully automatic disc filter precision ultrasonic cleaning system.

Desk-shaped filters, when the workpiece is set,

Type classification MARS-EH Specification liquid Pure water

- Automatically seal chuck the centre at the top and bottom and at the same time.

- Vacuum to remove air from the filter,

- After removal is complete, deaerated fluid is introduced.

- After immersion, rotate the desk filter and start ultrasonic cleaning.

- The first step in this process is to blow water out of the interior for a certain period of time.Backwashing and ultrasonic.

- After a further set time, the liquid starts to be sucked in and is positive rinsed and ultrasonic.

In other words, after the air has been completely removed, forward and backwashing are carried out at the same time, while rotating and moving up and down.

When the customer’s stainless steel wire becomes less than 3µ, even with a wide-range simultaneous multiple oscillator of 25 KHz to 275 KHz, the stainless steel wire will break at the welding point.Therefore, we have succeeded in efficiently oscillating double frequencies of 50 KHz to 275 KHz from the same oscillating element!The delivered machine automatically switches the fundamental frequency when a filter with 3µ stainless steel wire arrives.

Of course, if the basic frequency is switched, the liquid depth must also be changed, otherwise not only will the cleaning effect be reduced, but also the vibrating elements will be damaged.A fully automatic precision desk filter ultrasonic precision cleaning system, in which several of these automatic disc filter monofunctional machines are arranged in a row, automatically transported from the rack by robot and stored in the rack after cleaning, has also been delivered and is still active.

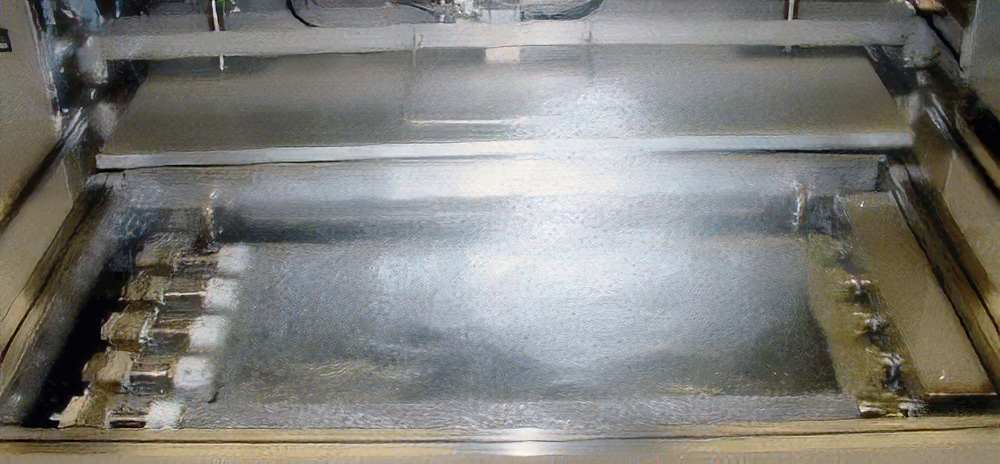

5 pleated filters simultaneously, vacuum pre-treatment type, ultrasonic cleaning system

Type classification MARS-EH-R

Pleated, five simultaneous automatic chuck vacuum pre-treatment, forward and backwash and precision ultrasonic cleaning systems have also been supplied.

Standard Engineering

- Filter set Horizontal lid in-situ check → Automatic start-up PBSW ON

- Horizontal aluminium vacuum lid closed → simultaneous chucking of filters → vacuum treatment

- Introduction of deaerated water → Cavitation strengthening and ultrasonic cleaning, forward rotation, simultaneous backwash, filtration circulation → Cavitation strengthening and ultrasonic cleaning, reverse rotation, simultaneous forward rotation, filtration circulation → Repeat until time up.

- Time up → Cleaning liquid level drops → Horizontal aluminium vacuum lid opens.

- Release the filter chuck → Take out the filter.

[Photo MARS example]

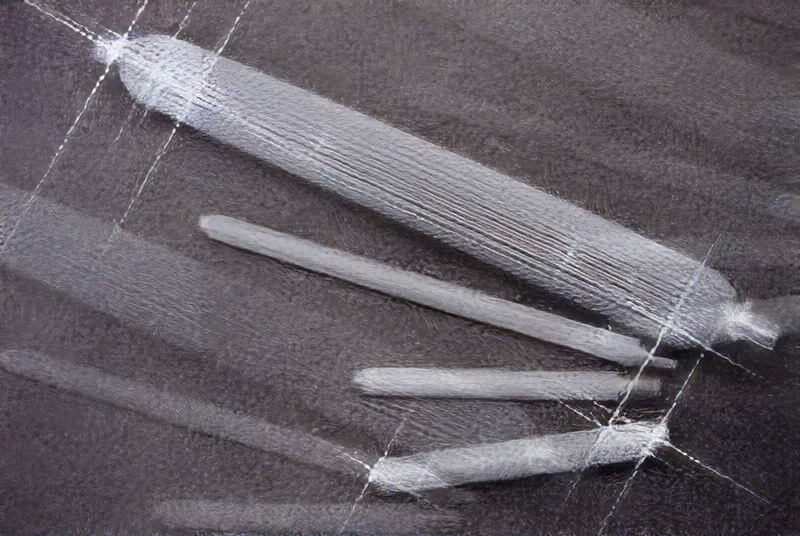

EOther filters cleaned and regenerated and cleaned (proven)

Filter cleaning technology is an important technology that can significantly help to halve the amount of waste, such as the regeneration and cleaning of turbines in thermal power stations and 700 mm square HEPA filters made of SUS frames.Please contact us for more information.

All rights reserved.