1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

APR version ultrasonic cleaning equipment

Eliminate misleading ultrasonic cleaning and adopt true ultrasonic cleaning technology!

- For the APR version of precision high-speed cleaning, use true ultrasonic cleaning spherical nebula cavities (microvacuum nuclei group).

For more information on his involvement with the APR plate washer, please refer to “APR Plate Cleaning System” in the Technical Information section of this website.

Having supplied many APR versions of ultrasonic cleaning systems, Blue Star R&D has now further developed its existing technology to offer a new, low-cost, precision cleaning system.

The APR version of the NMP → water cleaning technology is widely used these days, but shibano, our technical advisor, was the first in the industry to successfully develop this cleaning technology in cooperation with K.

APR version of one-cycle vertical transfer and ultrasonic cleaning equipment.

Set the PR plate on the jig.Switch on the automatic activation switch.The APR plate is inserted into the thin ultrasonic tank, which has a standard depth of 105 mm, width of the plate jig plus a 100 mm opening, and ultrasonic cleaning takes place.There is only one cleaning tank.NMP ultrasonic cleaning and water rinse ultrasonic cleaning are carried out in this tank.

Standard Engineering

- APR version In-situ mounting.Automatic start-up SW/ON.

-

APR Plate lowering and vertical far movement NMP ultrasonic cleaning This NMP ultrasonic cleaning is not a normal ultrasonic cleaning: NMP dissolves a lot of air.For this reason, ultrasonic irradiation cannot reliably clean the precision fine plates.

In order to remove air sufficiently quickly, it is necessary to remove air entering from the liquid surface and air that has been dissolved from the outset, and to generate countless spherical nebula-shaped cavities (microvacuum nuclei).The system that makes this possible is called the Cavitation Enhancement System.This is Blue Star R&D’s original technology.

50 KHz to 275 KHz, simultaneous multiple wave oscillation and fundamental frequency PowerSeep

For precise and sensitive APR versions, 25 KH, 40 KHz, etc. are not used. 50 KHz is used.Produces delicate, high-density spherical nebula cavities.The number of cavities is eight times higher than in the same conditions at 25 KHz, with cavities of numerous frequencies from 50 KHz to 275 KHz and a basic frequency sweep for even greater cleaning effectiveness.

- Vacuum rapid suction NMP recovery

- Pure water rinsing Ultrasonic cleaning NMPs are rinsed ultrasonically with pure water and prepared for drying.This pure water ultrasonic rinse also comes with a cavitation enhancement system.

- Lifting and lowering of APR plate Stop in-situ Take out Pure water drainage After this, the APR plate is set in the dryer.

APR version 2-tank automatic ultrasonic cleaning and drying system (manual and automatic)

Automatic two-tank APR version ultrasonic cleaning system in which the pure water ultrasonic rinsing of the APR version one-cycle automatic cleaning system is not performed in the same tank, but in the next pure water ultrasonic tank with a dedicated cavitation enhancement system, with liquid cut-off drying upon ascent.

Standard Engineering

- PR plate In-situ mounting.Automatic start-up SW/ON.

- APR plate lowering and vertical far movement NMP ultrasonic cleaning with cavitation enhancement system

- APR version up Move to tank 2

- APR version Descending Pure water ultrasonic rinse and wash

- Rapid discharge of pure water and drying of APR plate liquid cut.

- APR version In situ Ended

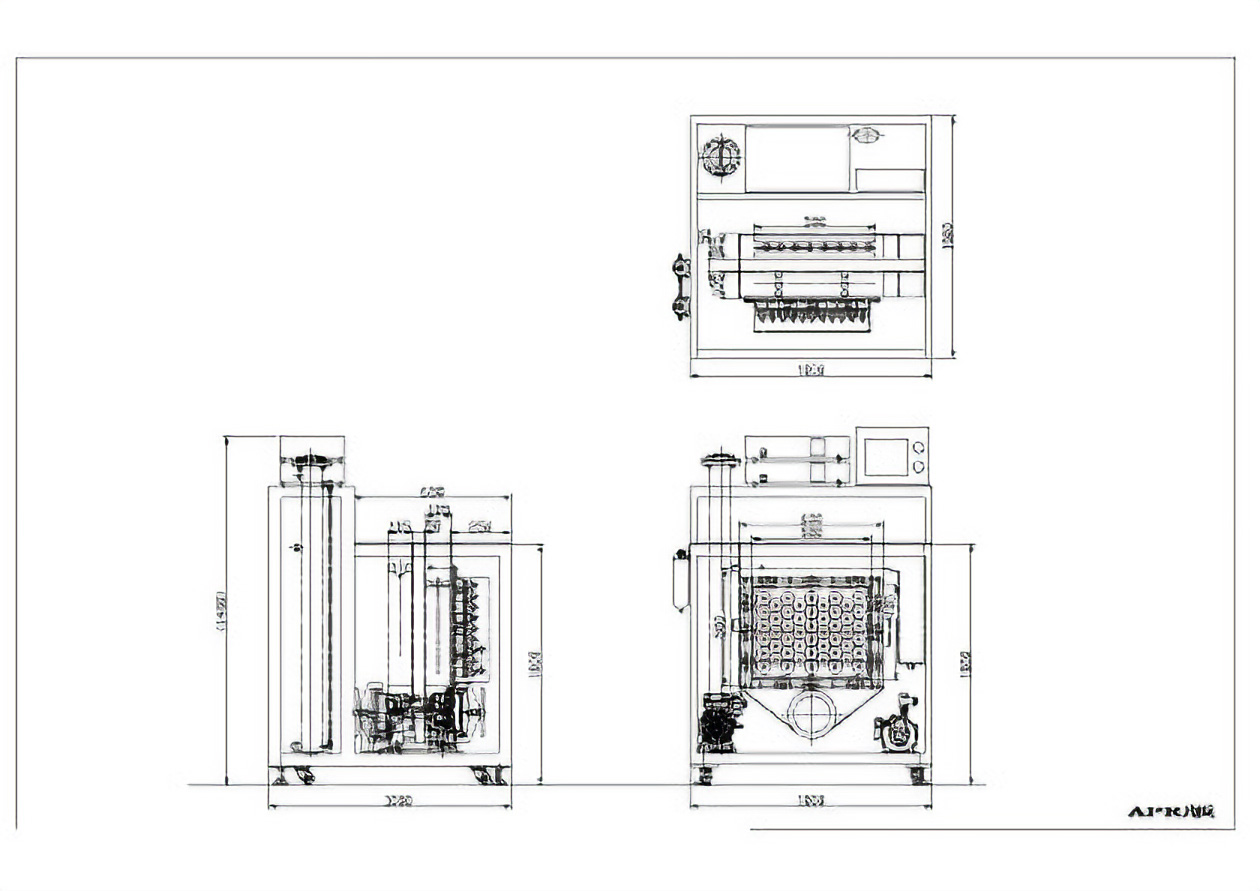

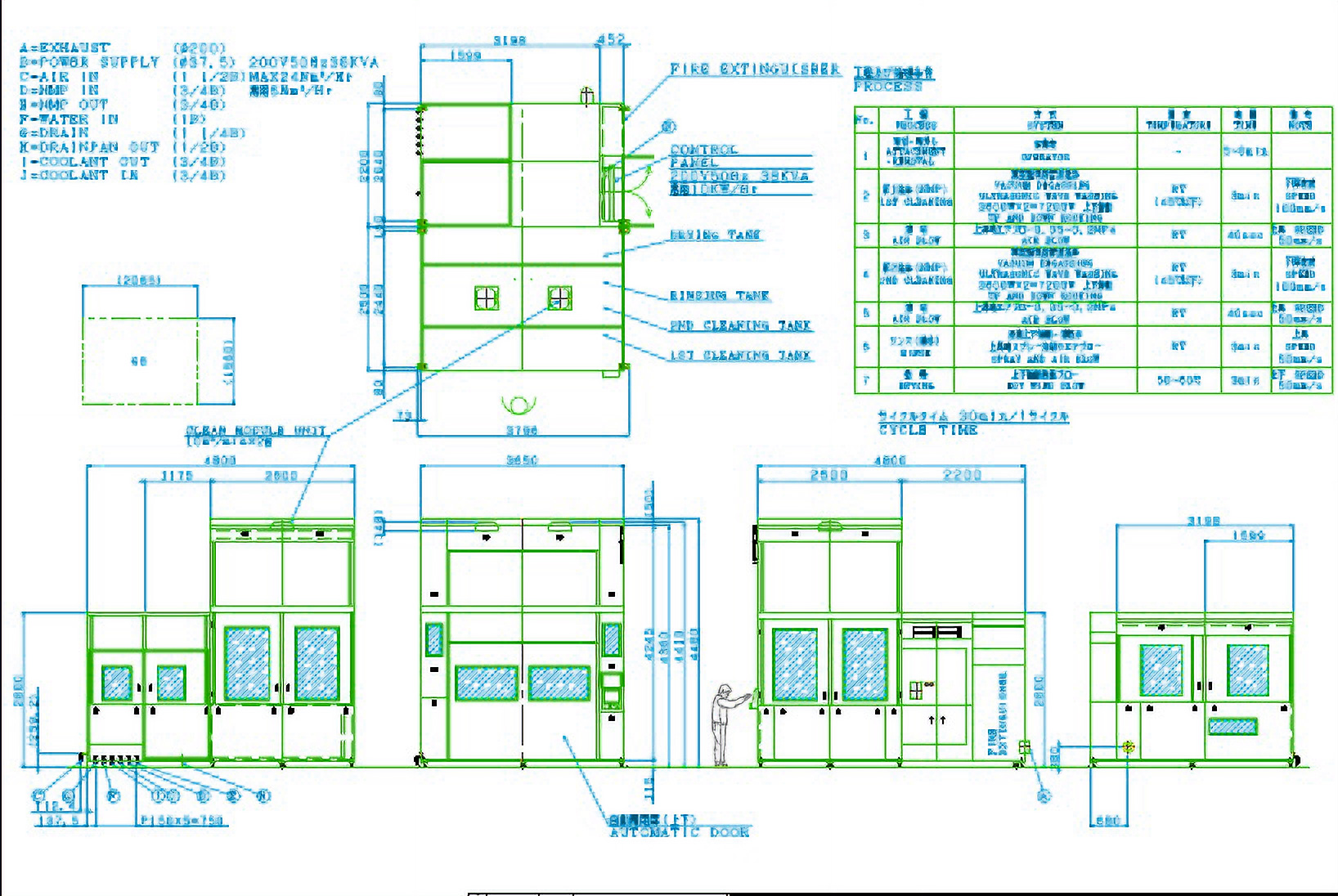

APR Version Fully Automatic Ultrasonic Cleaning Device G6 Example

The following case study drawings of an APR version of a fully automatic ultrasonic cleaning system are available.For further information, please contact us.

[Exterior view]

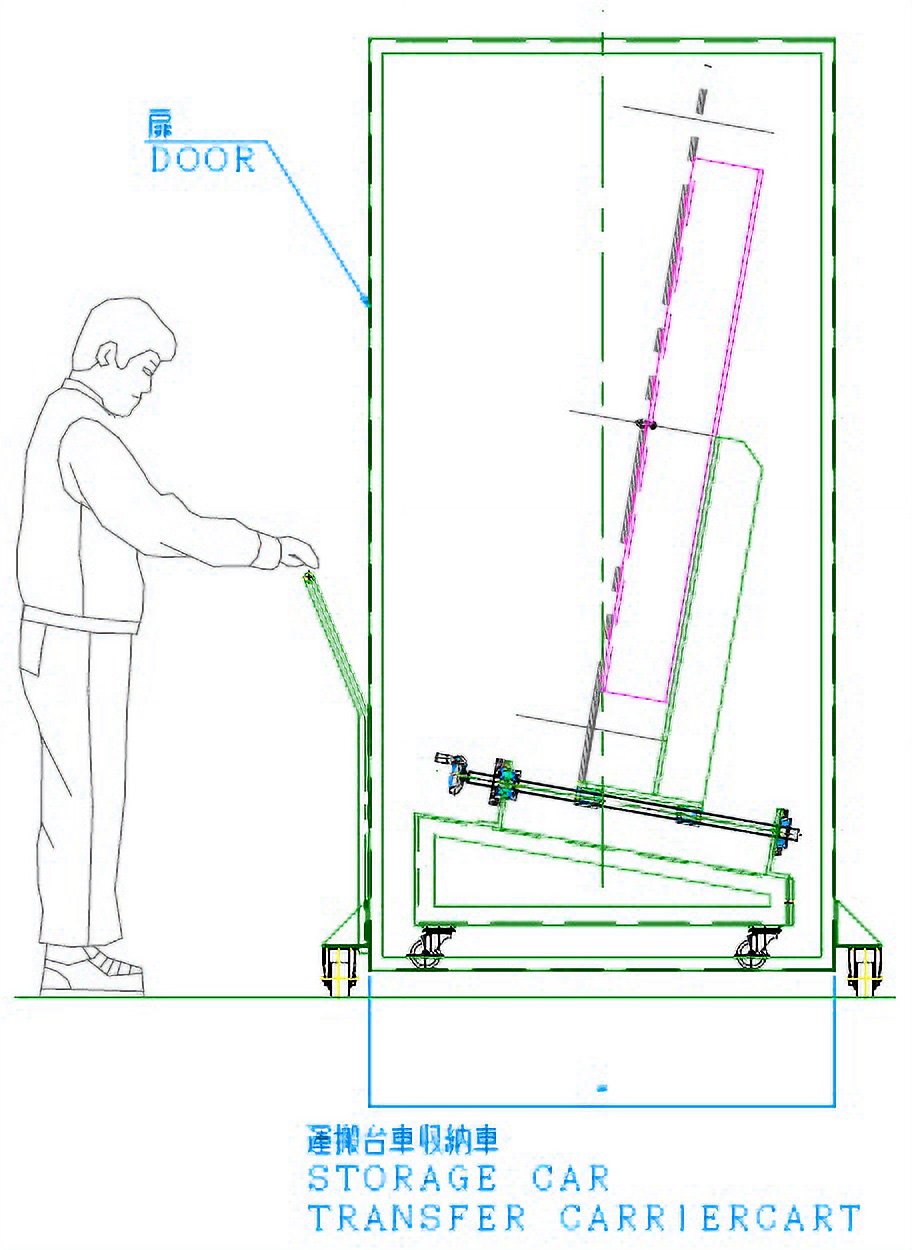

[Bogie]

All rights reserved.