1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

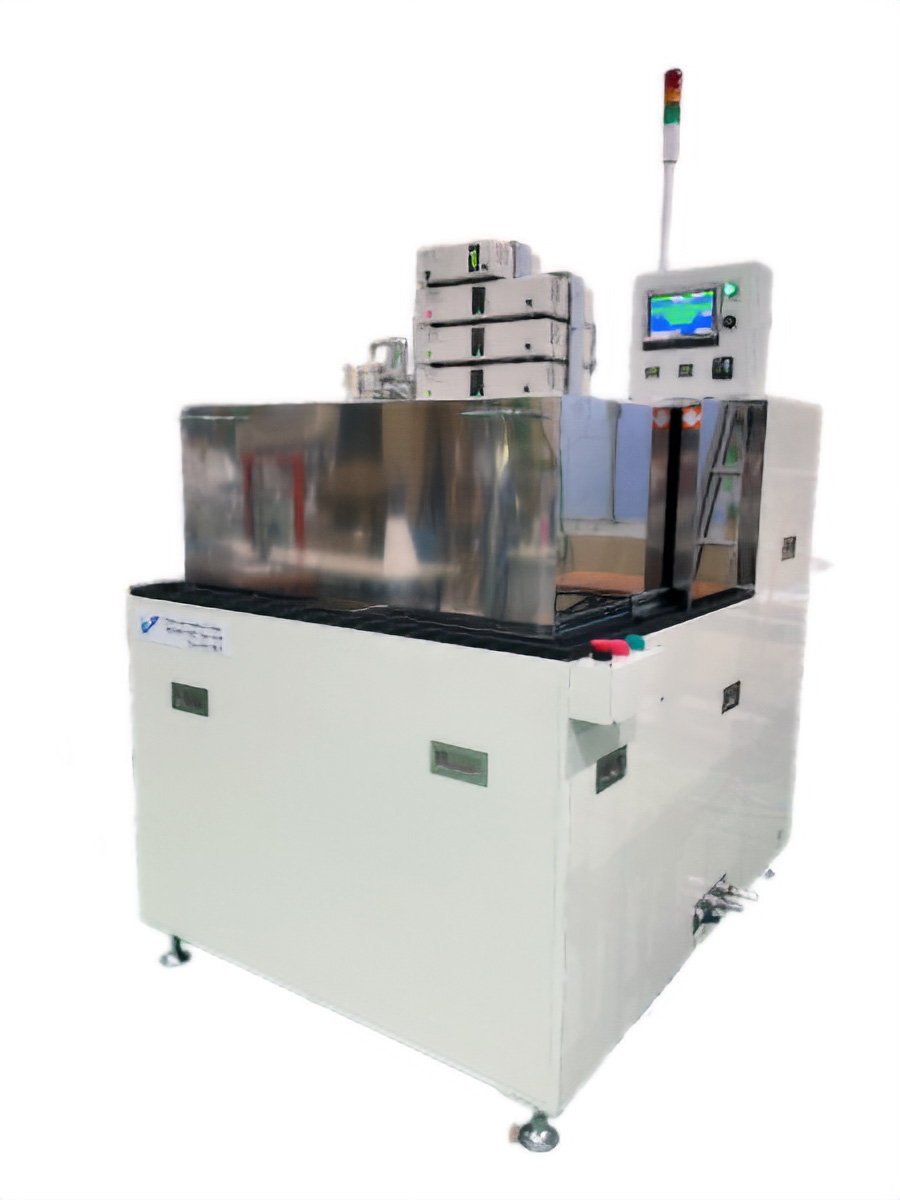

Ultrasonic cleaning equipment dedicated to moulds

Eliminate misleading ultrasonic cleaning and adopt true ultrasonic cleaning technology!

- A correct understanding of ultrasonic technology ensures precision cleaning of moulds.

- Hazardous chemicals and electrolysis technology are not required.

- Neutral cleaning agents are OK, sometimes even just water.

Our company has a long history of undertaking contract mould cleaning.We have used this experience to manufacture and deliver mould ultrasonic cleaning equipment in response to customer requirements, and we have also carried out ultrasonic deburring of moulds.We have now standardised our mould cleaning machines and are launching them domestically and internationally as part of the PERION series.

The time has come for precision cleaning of increasingly precise and evolving moulds, which cannot be handled by conventional gas nebula cavities or even by electrolytic ultrasonic cleaning based on gas nebula cavities.Our company makes maximum use of powerful spherical cavities (groups of micro vacuum nuclei) to generate a myriad of powerful positive and negative shock waves that can remove even burrs, making it possible to remove even the laminated glassy film surfaces that have sublimated and welded to every corner of the mould, not to mention the grain surfaces.

We invite you to watch a video of a true ultrasonic cleaning spherical nebula cavity on our YouTube screen.

Ultrasonic cleaners with ultrasonic cavitation enhancement systems are now available for the world of mould cleaning.As electrolysis is not used, no special cleaning agents are required.Running costs are also significantly reduced.No need to worry about hazardous ions leaching out.Anyone can use it safely anywhere in the world, both domestically and internationally!Powerful mould ultrasonic cleaning system.

PERION-Mm Mould ultrasonic cleaning equipment Target industry

PERION-Mm-1200 series with cavitation enhancement system

| Model | PERION-Mm-1200-1(Normal type) | PERION-Mm-1200-2(Double output type) | |

|---|---|---|---|

| Detergent | Water-Soluble | Alkaline Surfactant | Alkaline Surfactant |

| Ultrasonic output | W | 1200 | 1200 |

| Ultrasonic power density | W/cm2 | 1.0 | 2.0 |

| Ultrasonic frequency | KHz | (1)25 (2)25~275 | (1)25 (2)25~275 |

| カBasket shape(internal dimensions) | mm | W400×L300×H100 | W300×L200×H80 |

| Mould weight(MAX) | Kg | 55 | 45 |

| Tank dimensions | mm | W480×L360×H200[effective depth of liquid]165 | W360×L270×H180[effective depth of liquid]105 |

| Circulatory filter | 1unit | 3φ200V370W 20μ | 3φ200V370W 20μ |

| Heating heater | 1unit | 3φ200V 3KW | 3φ200V 2KW |

| Vacuum Begasser | Yes/No | Yes:Vacuum pump 200W | Yes:Vacuum pump 200W |

| Equipment Shape | mm | W700×L650×H1200 | W700×L650×H1200 |

| Electrical Power | KW | 3φ200V 5.0KW | 3φ200V 4.0KW |

| Equipment Weight | Kg | 65 | 60 |

| Explanatory N ote | Specification details are subject to change due to improvements. Please enquire in advance. Please ask separately for hydrocarbon solvents and mould cleaning machines. |

||

PERION-Mm-2400 series with cavitation enhancement system

| Model | PERION-Mm-2400-1(Normal type) | PERION-Mm-2400-2(Double output type) | |

|---|---|---|---|

| Detergent | Water-Soluble | Alkaline Surfactant | Alkaline Surfactant |

| Ultrasonic output | W | 2400 | 2400 |

| Ultrasonic power density | W/cm2 | 1.0 | 2.0 |

| Ultrasonic frequency | KHz | (1)25 (2)25~275 | (1)25 (2)25~275 |

| カBasket shape(internal dimensions) | mm | W600×L400×H100 | W400×L300×H100 |

| Mould weight(MAX) | Kg | 75 | 60 |

| Tank dimensions | mm | W660×L480×H200[effective depth of liquid]165 | W480×L360×H200[effective depth of liquid]165 |

| Circulatory filter | 1unit | 3φ200V370W 20μ | 3φ200V370W 20μ |

| Heating heater | 1unit | 3φ200V 3KW | 3φ200V 3KW |

| Vacuum Begasser | Yes/No | Yes:Vacuum pump 350W | Yes:Vacuum pump 350W |

| Equipment Shape | mm | W850×L850×H1200 | W850×L850×H1200 |

| Electrical Power | KW | 3φ200V 6.5KW | 3φ200V 6.5KW |

| Equipment Weight | Kg | 95 | 93 |

| Explanatory N ote | Specification details are subject to change due to improvements. Please enquire in advance. Please ask separately for hydrocarbon solvents and mould cleaning machines. |

||

PERION-Mm-3600, 4800 series with cavitation enhancement system

| Model | PERION-Mm-3600-2(Double output type) | PERION-Mm-3600-2(Double output type) | |

|---|---|---|---|

| Detergent | Water-Soluble | Alkaline Surfactant | Alkaline Surfactant |

| Ultrasonic output | W | 3600 | 3600 |

| Ultrasonic power density | W/cm2 | 2.0 | 2.0 |

| Ultrasonic frequency | KHz | (1)25 (2)25~275 | (1)25 (2)25~275 |

| カBasket shape(internal dimensions) | mm | W500×L360×H120 | W500×L360×H120 |

| Mould weight(MAX) | Kg | 70/td> | 75 |

| Tank dimensions | mm | W600×L420×H200[effective depth of liquid]165 | W660×L480×H200[effective depth of liquid]165 |

| Circulatory filter | 1unit | 3φ200V370W 20μ | 3φ200V370W 20μ |

| Heating heater | 1unit | 3φ200V 3KW | 3φ200V 3KW |

| Vacuum Begasser | Yes/No | Yes:Vacuum pump 350W | Yes:Vacuum pump 350W |

| Equipment Shape | mm | W850×L850×H1200 | W850×L850×H1200 |

| Electrical Power | KW | 3φ200V 9.5KW | 3φ200V 11.5KW |

| Equipment Weight | Kg | 120 | 135 |

| Explanatory N ote | Specification details are subject to change due to improvements. Please enquire in advance. Please ask separately for hydrocarbon solvents and mould cleaning machines. |

||

New ultrasonic cleaning equipment dedicated to ultrasonic liquid surface installation and moulds.

Dear Customer.

The demand for powerful precision cleaning of moulds has been very strong in recent years.We have cleaned and delivered a wide range of moulds in response to requests for mould cleaning.Based on this experience, we have decided to manufacture and sell a powerful ultrasonic mould cleaner based on the correct control of cavitation by ultrasonic waves.The main features of our PERION-Mm mould cleaning machine are explained below.

-

Ultrasonic oscillators and transducers SIRIUS Features

- Ultrasonic cleaning is a cleaning method that applies the physical force of the impact force generated by ultrasonic waves when cavities (groups of micro vacuum nuclei) are created and annihilated to cleaning.

Therefore, the quality of the ultrasonic oscillator depends on how efficiently and stably the cavities that generate the desired impact force can be generated.

Our ultrasonic oscillators have been developed and designed for this purpose.The frequency is the easy-to-use 25 KHz fundamental frequency, to which higher frequencies from 50 to 275 KHz are added. The synergistic effect of the creation of a large cavity by the sound pressure change of the fundamental frequency and the cavities of many other high frequencies increases the cleaning power.

The shape of the tank is designed using the fundamental frequency, so that cavities can be generated and managed in a stable manner. Frequently seen alternating multi-frequencies that SWEEP the fundamental frequency to a large extent are a design error that does not know the principle of cavity generation.

- The transducers are assembled to oscillate a large number of ultrasonic vibration elements in parallel, and each element is individually inspected and quality-controlled after assembly. After delivery, the entire system is managed in 600 W units, so that any partial abnormality can be corrected. This is a technology unique to our company and an important feature that differs from conventional types, which look at the whole system at once (abnormalities here cannot be identified in advance).

- Ultrasonic cleaning is a cleaning method that applies the physical force of the impact force generated by ultrasonic waves when cavities (groups of micro vacuum nuclei) are created and annihilated to cleaning.

- Ultrasonic cleaning tanks and cavitation control

No matter how good an oscillator is built, it is meaningless unless the cleaning tank that receives it is designed correctly. The design of the liquid depth (reflection design) corresponding to the fundamental frequency, the width and depth of the tank, the flow of the liquid and temperature control. Stable ultrasonic cleaning is only possible when the cleaning tank is correctly designed to generate stable cavitation in the liquid, in other words, when it is designed for cavity control. In most ultrasonic tanks, this simple but most important aspect is not followed. -

Cavitation enhancement systems and cavity types.

- Ultrasonic cleaning, biggest misconceptions and countermeasures

It was announced and made public knowledge at an international conference in Washington in 1993 that the visible bubbles generated in liquids by ultrasound are air bubbles, which eliminate or suppress ultrasound waves. In other words, if visible bubbles are generated during ultrasonic irradiation, the ultrasonic waves have largely disappeared on the surface of the diaphragm. This phenomenon invariably occurs in liquids other than water (which dissolves many gases).

The system for removing (degassing) the dissolved gases contained in this liquid to achieve true ultrasonic cleaning is named the Cavitation Enhancement System.

[Ultrasonic waves disappear on the surface of the diaphragm due to bubbles.] - Water has a particularly low dissolved air content among liquids, with an oxygen content of 6-8 mg/ℓ. This causes cavities (groups of microvacuum nuclei) to form, but they are misshapen and cannot be cleaned in a strong, stable manner.

The cavities appear as white streaks, but the individual cavities are collapsed and have a gas nebula shape. They are gathered together and lined up horizontally, giving them a streaky appearance. Cannot be used for cleaning moulds. The cleaning power is very weak. Degreasing and removal of chips is possible.

- Cavitation enhancement systems, application of spherical nebula type cavities.

The following cavitation distribution and spherical nebula cavities occur when dissolved gases (air) are removed from all liquids, including water, and can be managed in an ultrasonic tank with cavitation control.

Globular nebula cavity

These cavities move perpendicular to the diaphragm countless times, enabling powerful, precision cleaning.

Without these cavities, modern precision mould cleaning would be impossible.Our PERION-Mm mould cleaning machine is designed to make efficient use of these cavities.

- Ultrasonic cleaning, biggest misconceptions and countermeasures

- Type and selection of cleaning solutions

Ultrasonic cleaning is a physical cleaning method that uses the impact force generated when ultrasonic cavities are created and extinguished in a liquid. Cavities do not have the ability to dissolve. It is a peeling and dispersing ability.

Cleaning solutions must therefore be selected to suit the purpose.

The removal of oil, resins and rubber itself is often done by electrolytic ultrasonics (this is typical of ultrasonics, which do not understand electrolysis or electric fields at all). ), etc., are out of the question and often require alkaline cleaning agents. However, if it is only baked-on or carbon-based, water alone is often sufficient, assuming the use of strong cavities.

Impact forces on spherical cavities are higher at lower temperatures. Therefore, in many cases, water is sufficient for precision mould cleaning, assuming the customer is strong enough.

- PERION-Mm series Mould ultrasonic cleaners Features

It is designed with all the features of our ultrasonic cleaning technology.

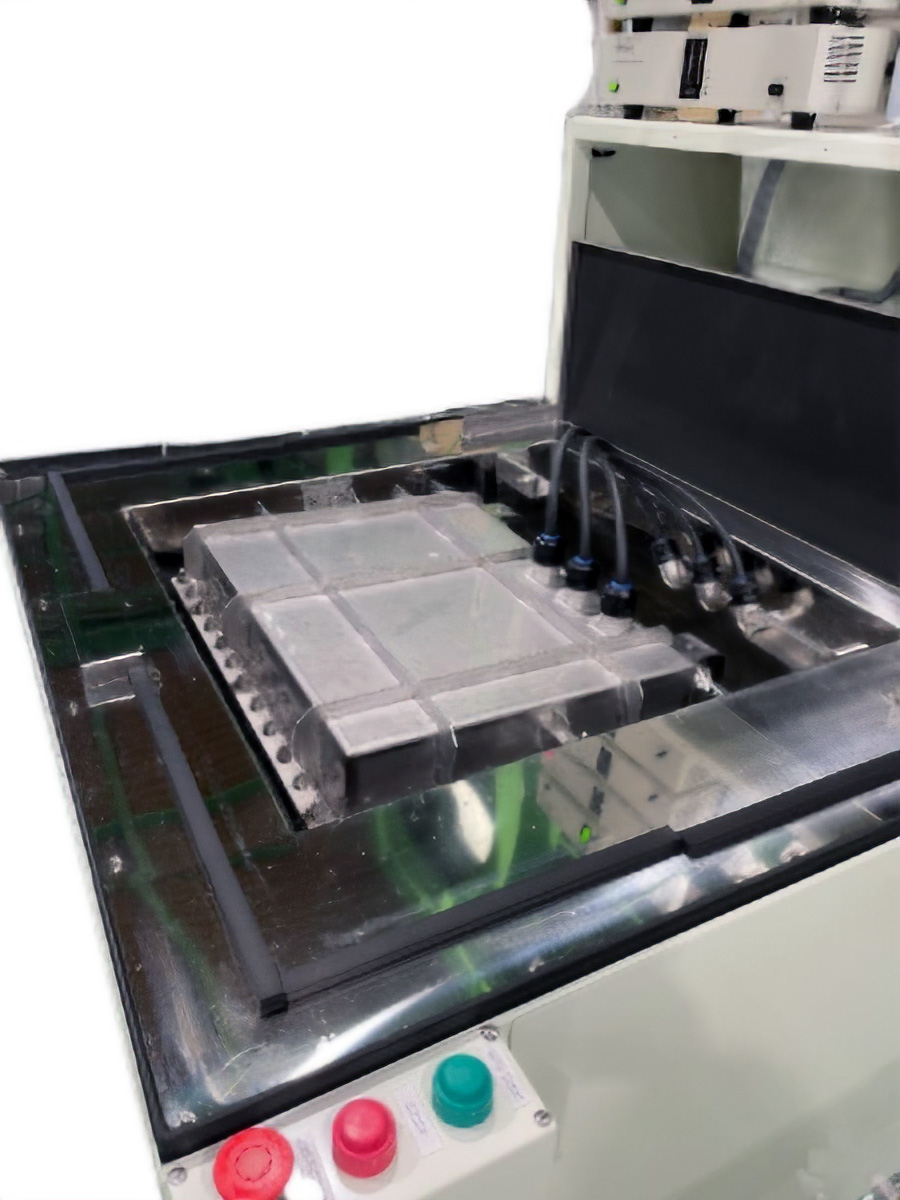

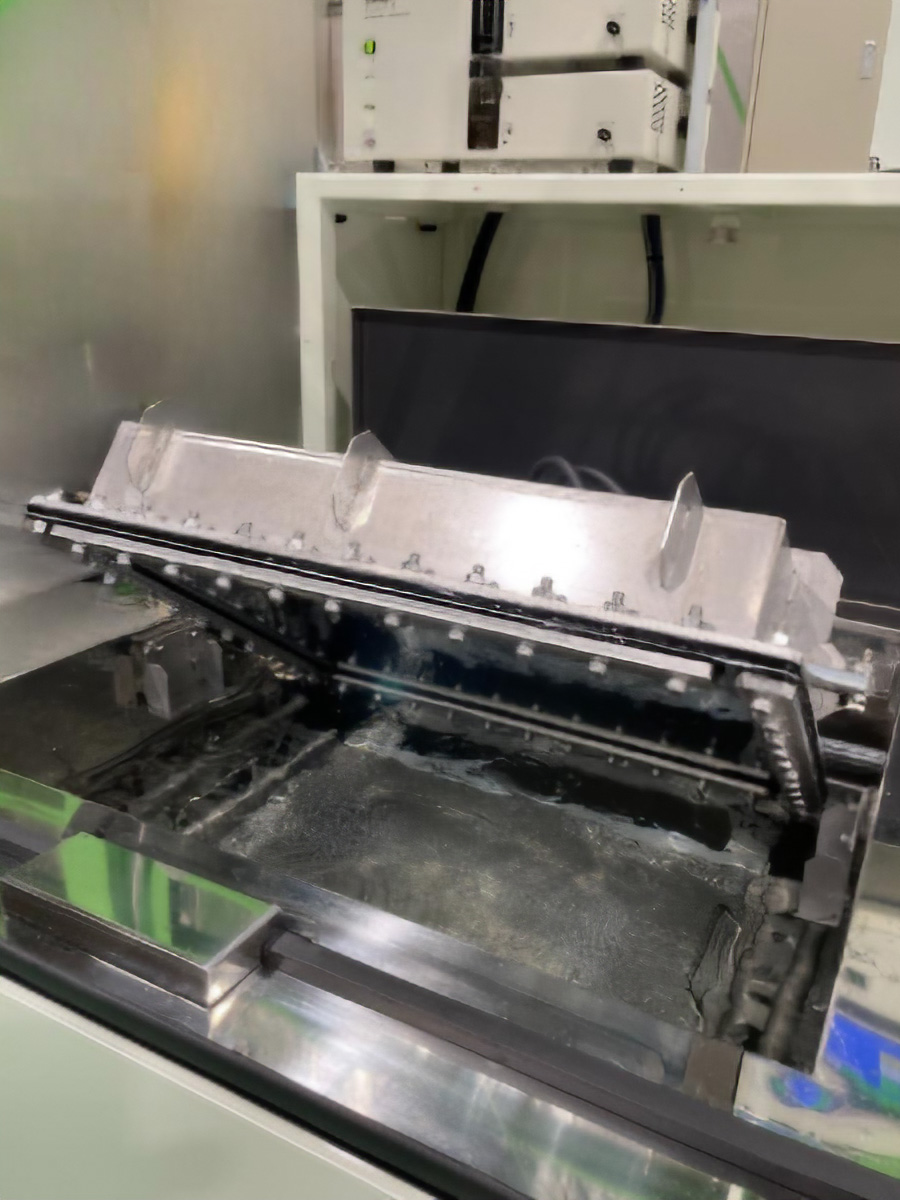

Automatic control items include liquid temperature (if equipped with chiller), degassing capacity (vacuum control), ultrasonic waves (abnormality alarm), filter (filtration pressure), etc. Simply place the mould in the basket, close the lid and press the start-up PBSW to perform powerful ultrasonic cleaning while the basket moves up and down for the time set on the touch screen in advance. If the lid is not closed, ultrasonic waves will not be applied.

Liquid is water in principle.

It is a standard machine that anyone can use immediately.

Example of PERION-Mm-2400

All rights reserved.