1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

Gravure cylinder ultrasonic cleaning system

Eliminate misleading ultrasonic cleaning Adopt true ultrasonic cleaning technology!

- For our customers, we recommend the use of the Gravure Cylinder Ultrasonic Cleaning System, which has an amazing cleaning power.

Environmentally friendly, high-performance cleaning power, low-cost cleaning equipment for the age of globalisation.

Gravure cylinder ultrasonic cleaning system

No solvents are used and environmentally friendly cleaning agents of weak alkaline type are used for precision cleaning of delicate gravure cylinders.Manual ultrasonic cleaning tanks and one-cycle automatic ultrasonic cleaning tanks are introduced here.

Proof of unparalleled cleaning power.

Cavities of other companies

The cavities that look like white clouds are ordinary water-based ultrasonic cleaning cavities.This cavity cannot be used to clean gravure cylinders.You have to rely on solvents. In China, you can’t watch YouTube, so I’m posting this on YouKu.

See here.

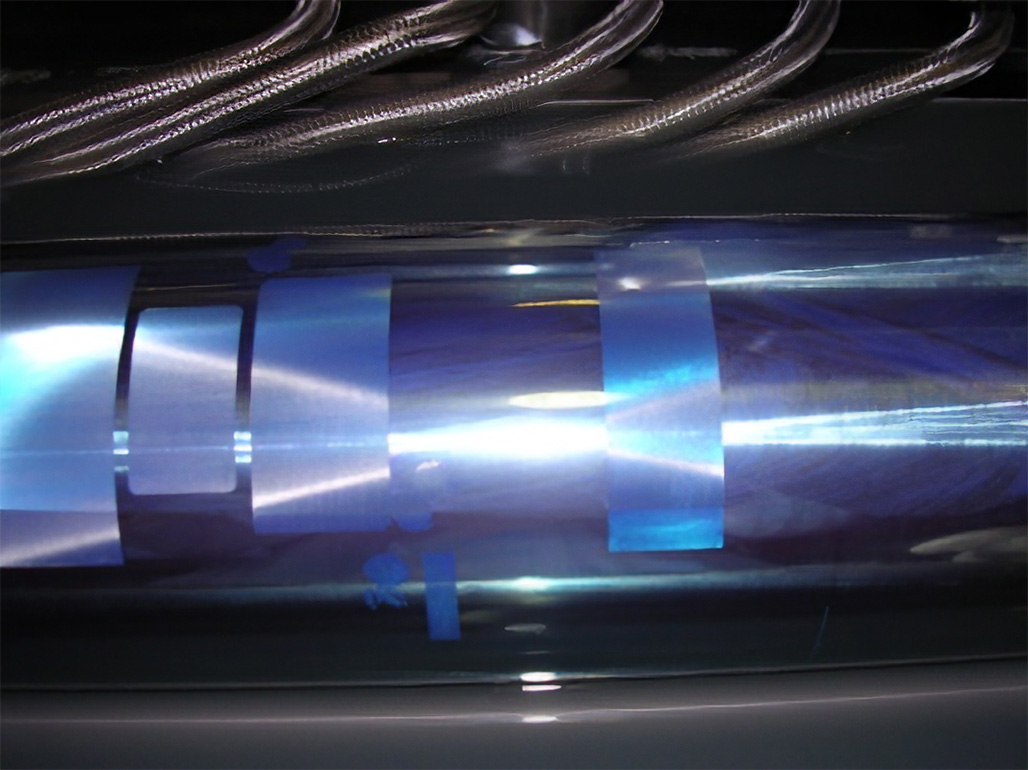

Blue Star R&D cavity.

White spherical vacuum nuclei moving vertically.This is Blue Star R&D’s unique spherical vacuum nuclei – spherical nebula cavities – which provide excellent cleaning power.This is how we clean your precious gravure cylinders safely and precisely. In China, YouTube is not available, so this video is available on YouKu.Please see here.

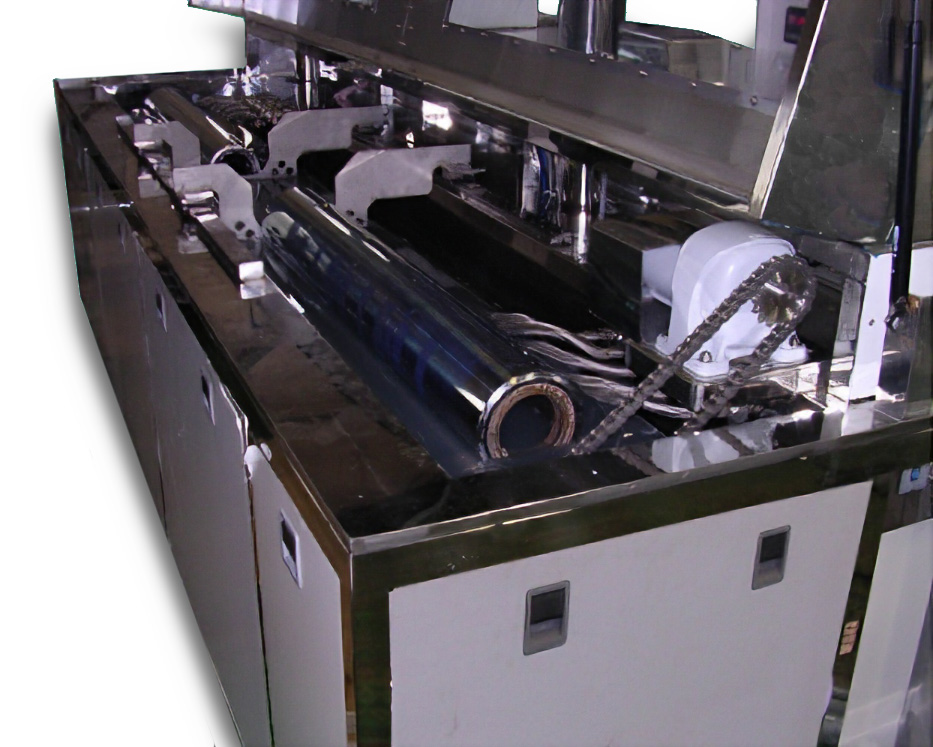

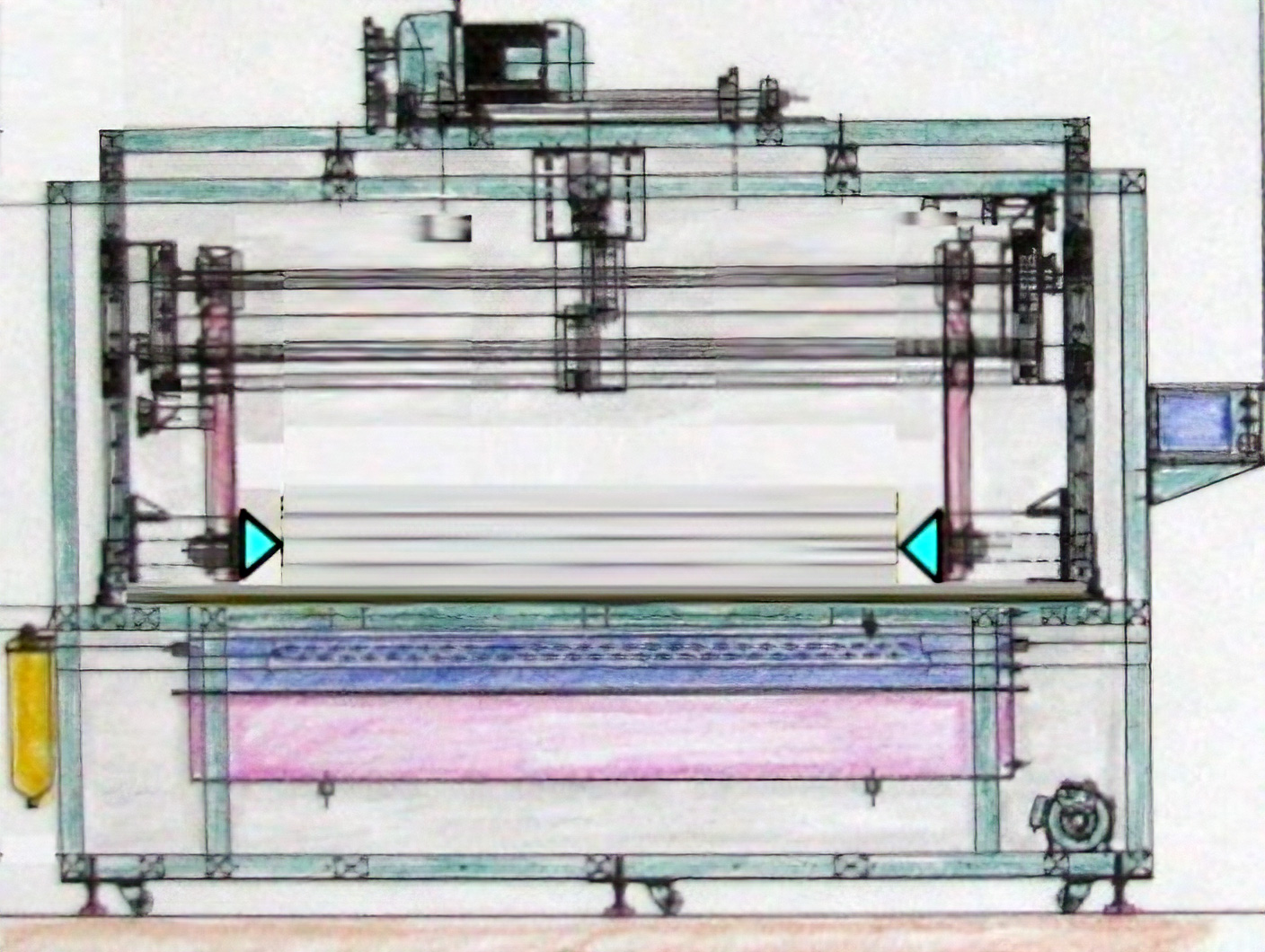

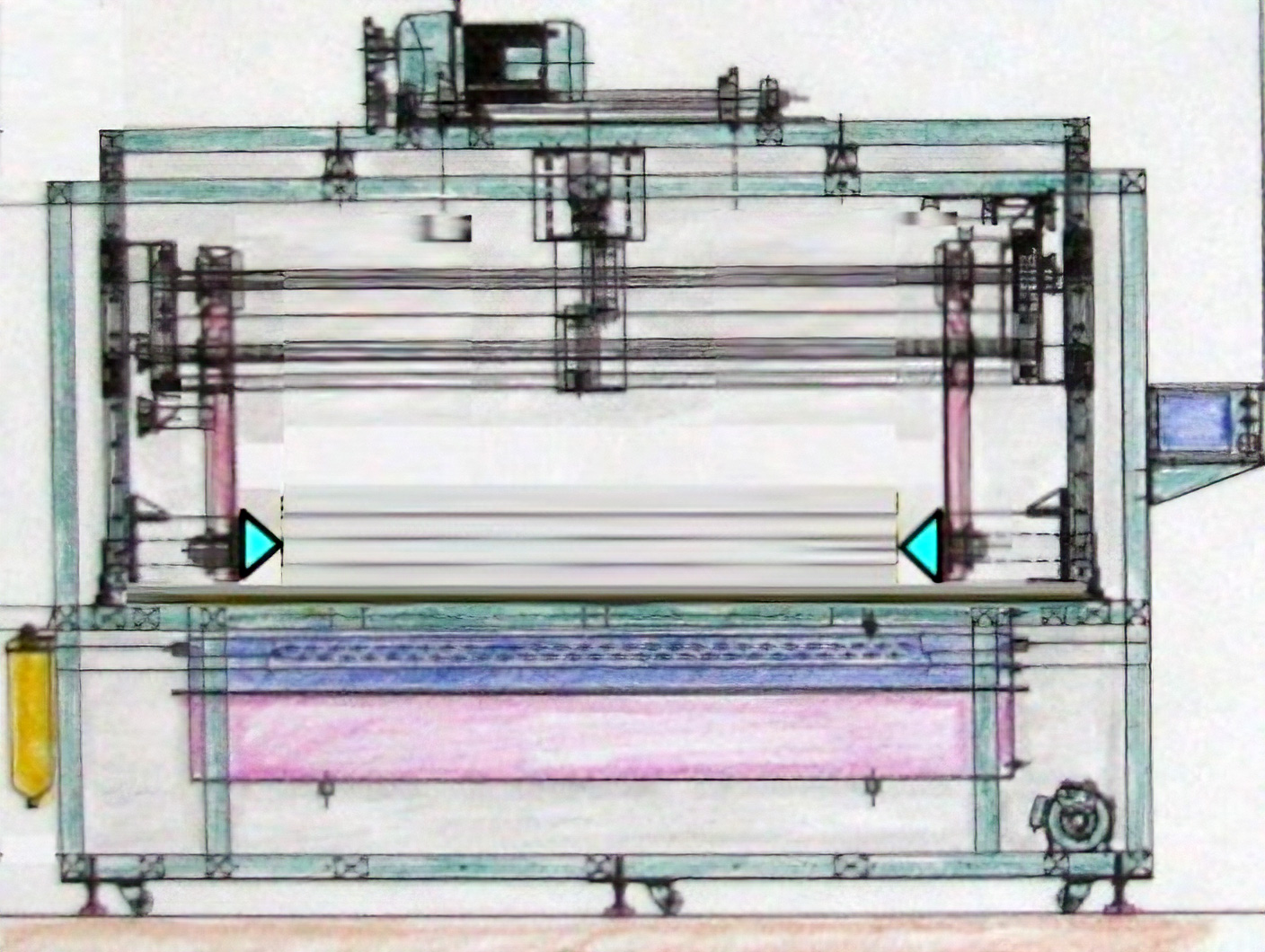

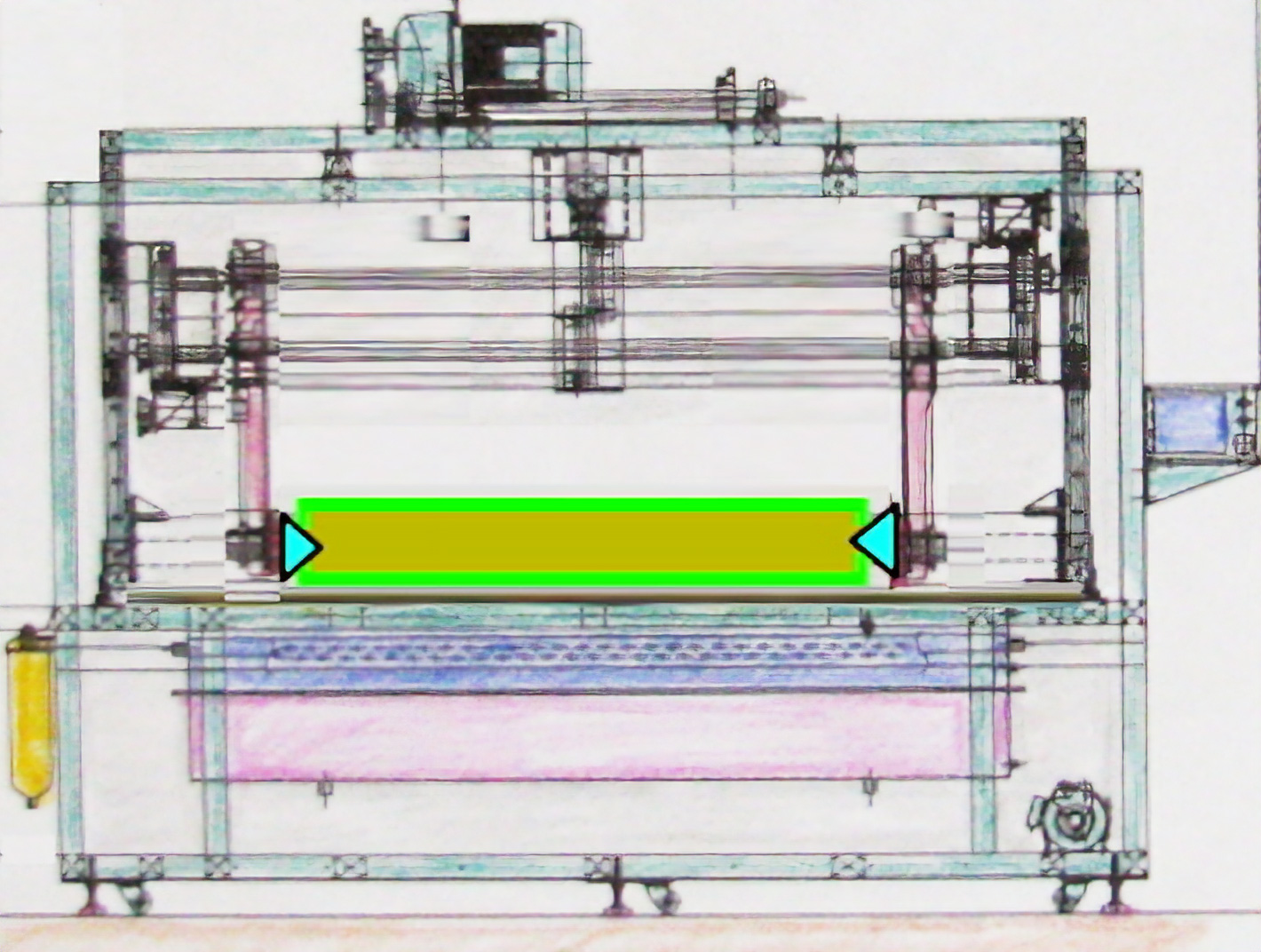

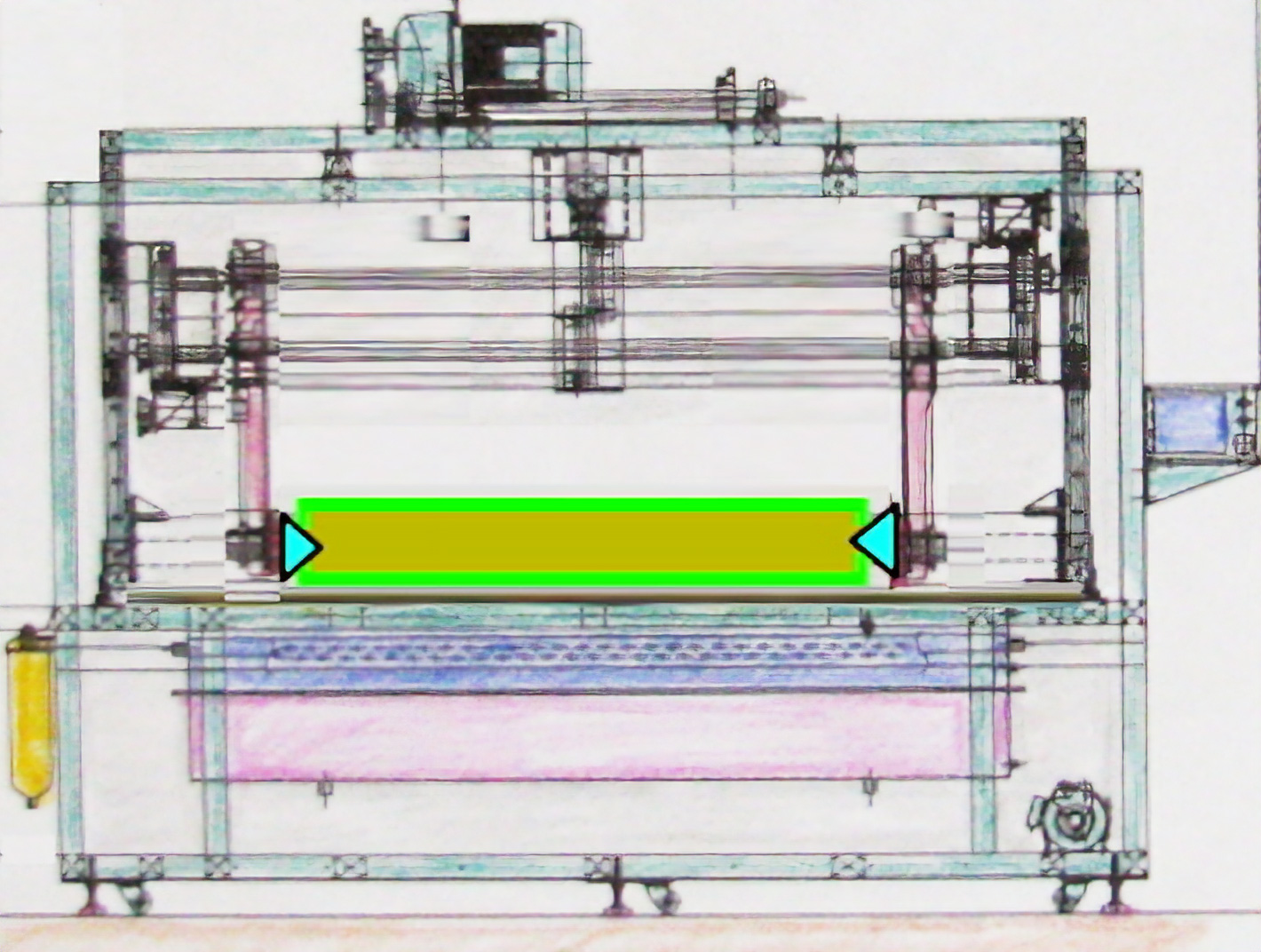

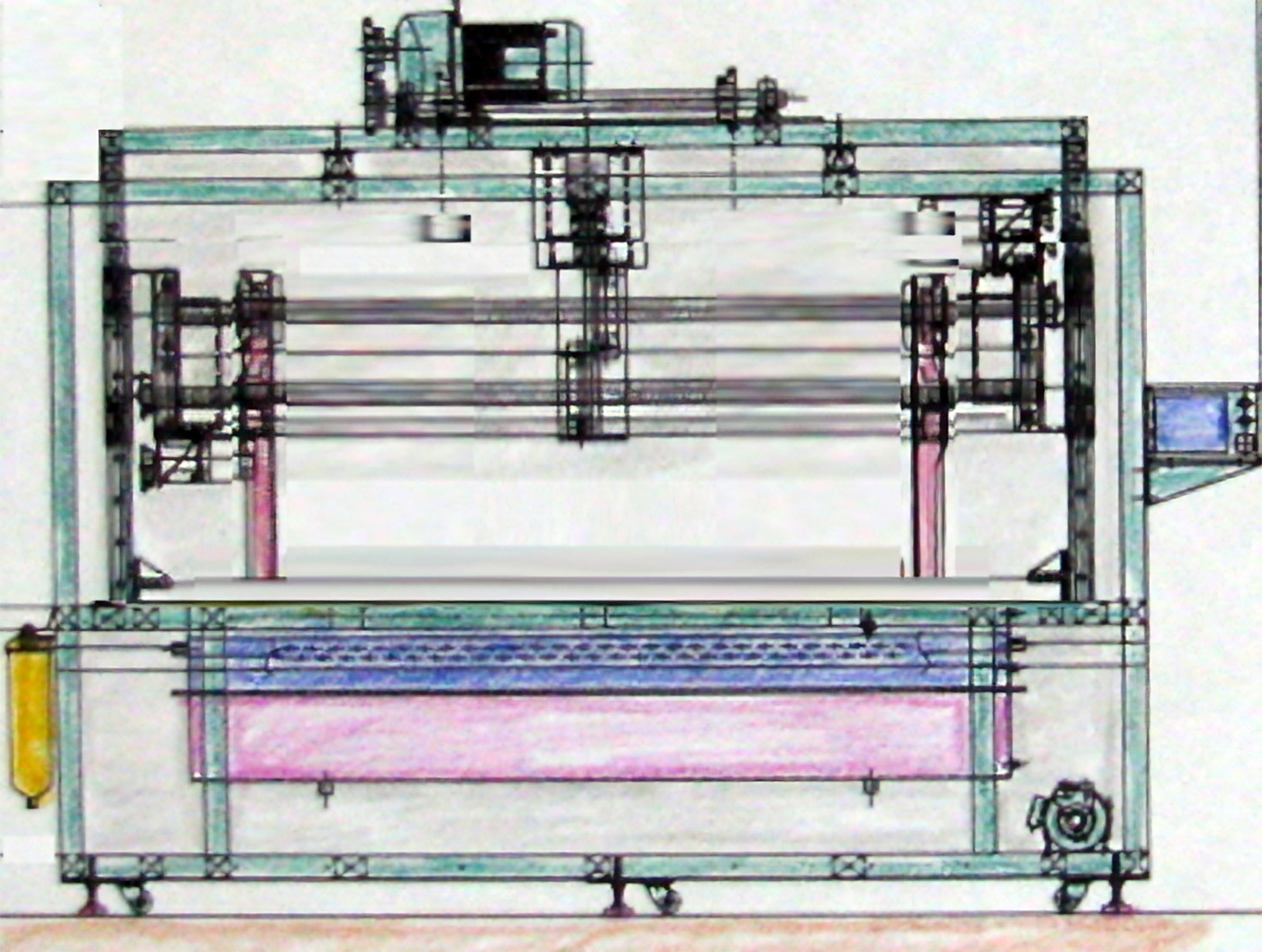

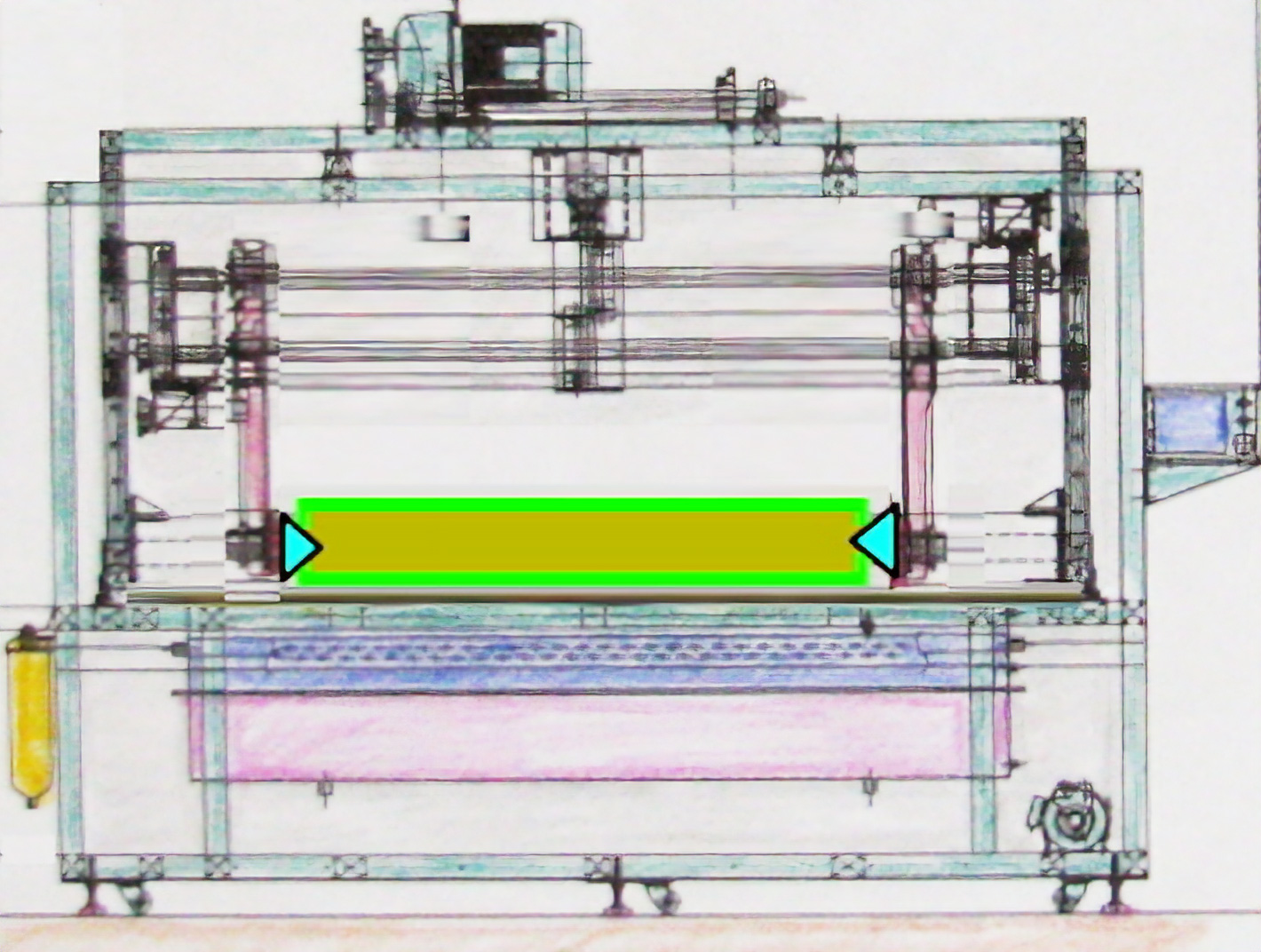

Manual and gravure cylinder cleaning equipment

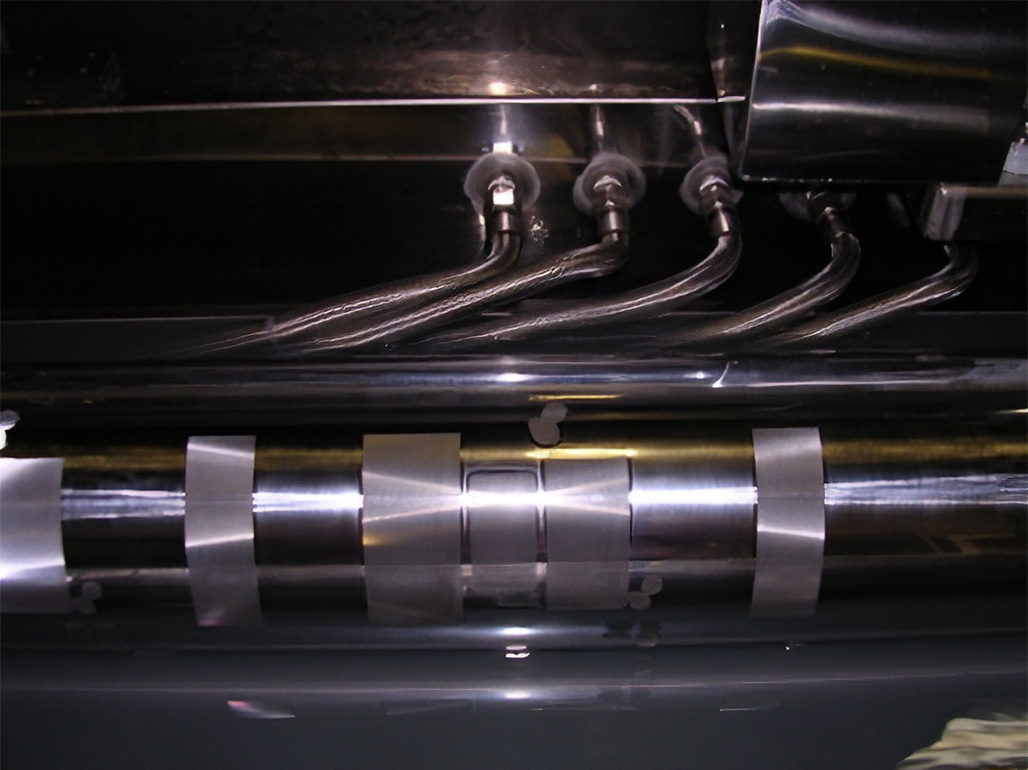

The gravure cylinder is placed on the position-adjustable rotating rollers and the cylinder is ultrasonically cleaned while rotating.Of course, it comes with our special technology, the Cavitation Enhancement System.A rotating brush can also be fitted for end-face cleaning.

Basic specification

[Example of equipment specification]

The machine specifications are as follows.Dimensions are subject to change due to technical improvements, so please enquire in advance.

| Target cylinder shape and size | Sleeve type Diameter 127φ-230φ Face length 850mm-1,300mm Maximum weight 70kg |

|---|---|

| Surface to be cleaned | Cylindrical part (ultrasonic cleaning) End face (brush cleaning) |

| Setting the cylinder into the device | Manual (automatic setting available as an option) Cylinder diameter change ⇒ Manual adjustment of roller position Cylinder length change ⇒ Manual adjustment of driven rotating roller position |

| Cleaning time | Approx. 5minutes (cleaning time varies depending on ink type, degree of adhesion and leaving time). |

| Detergent | Alkaline water-soluble cleaning agents |

| External dimensions and weight | W3,530×D1,500×H2,200 1,300kg |

| Sonicator | SIRIUS-6000 6,000W×1unit(25KHz~275KHz) |

| Cavitation enhancement system | V-unit L-typex1 Vacuum pump 310Wx1 Vacuum control system×1set Suction pump 310W×1unit |

| Recirculating filter | Circulation pump 310W×1unit 20µW filter×1set |

| Rotary motor | 1gird motor 200W(with speed control) |

| Cylinder rotation speed | mm/sec |

| Primary power supply | three phases 200V 25KWA |

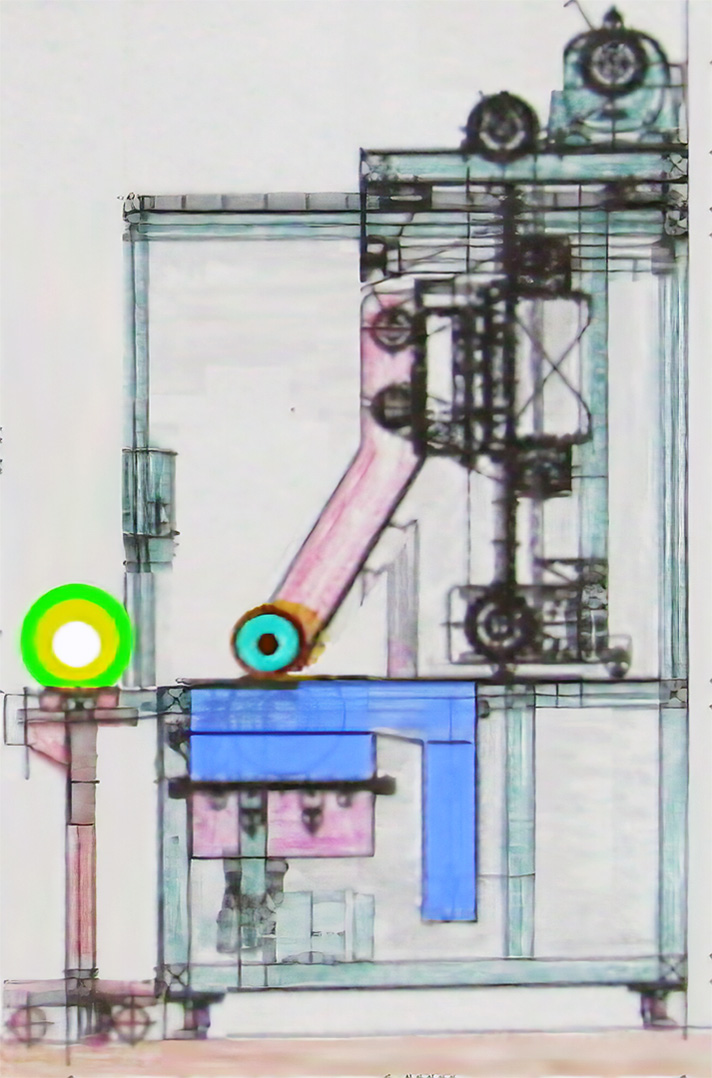

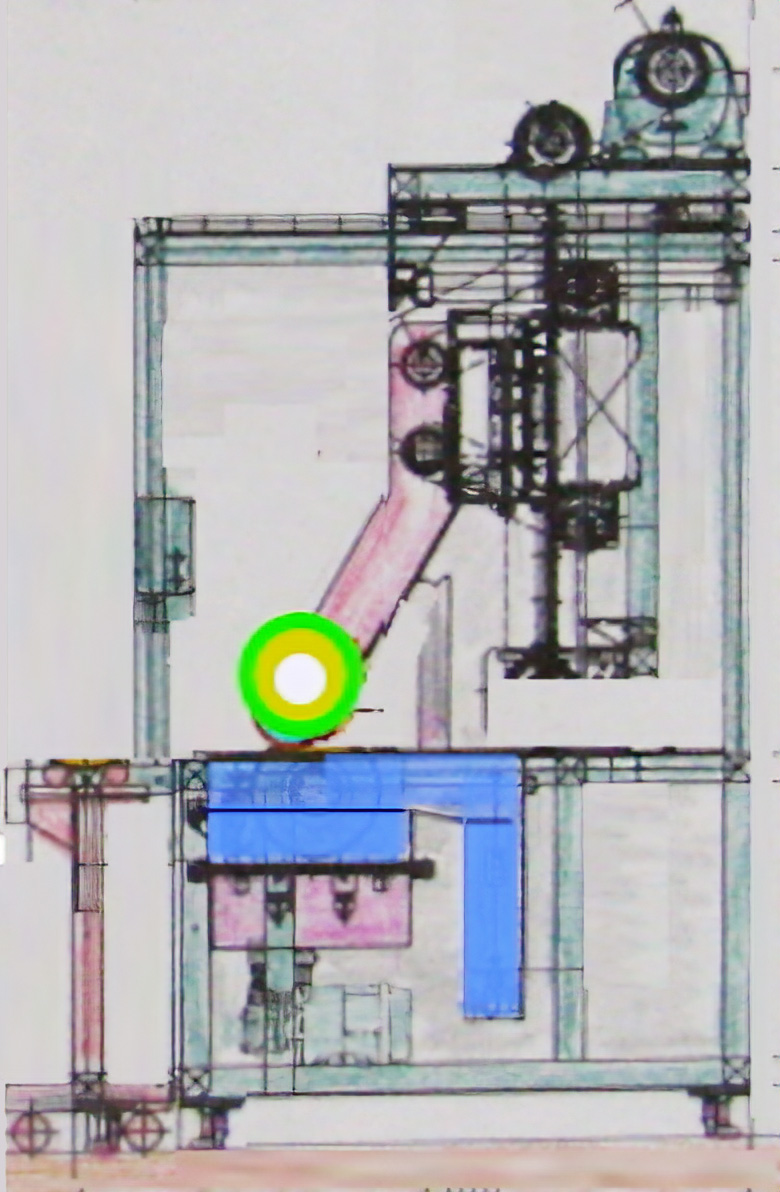

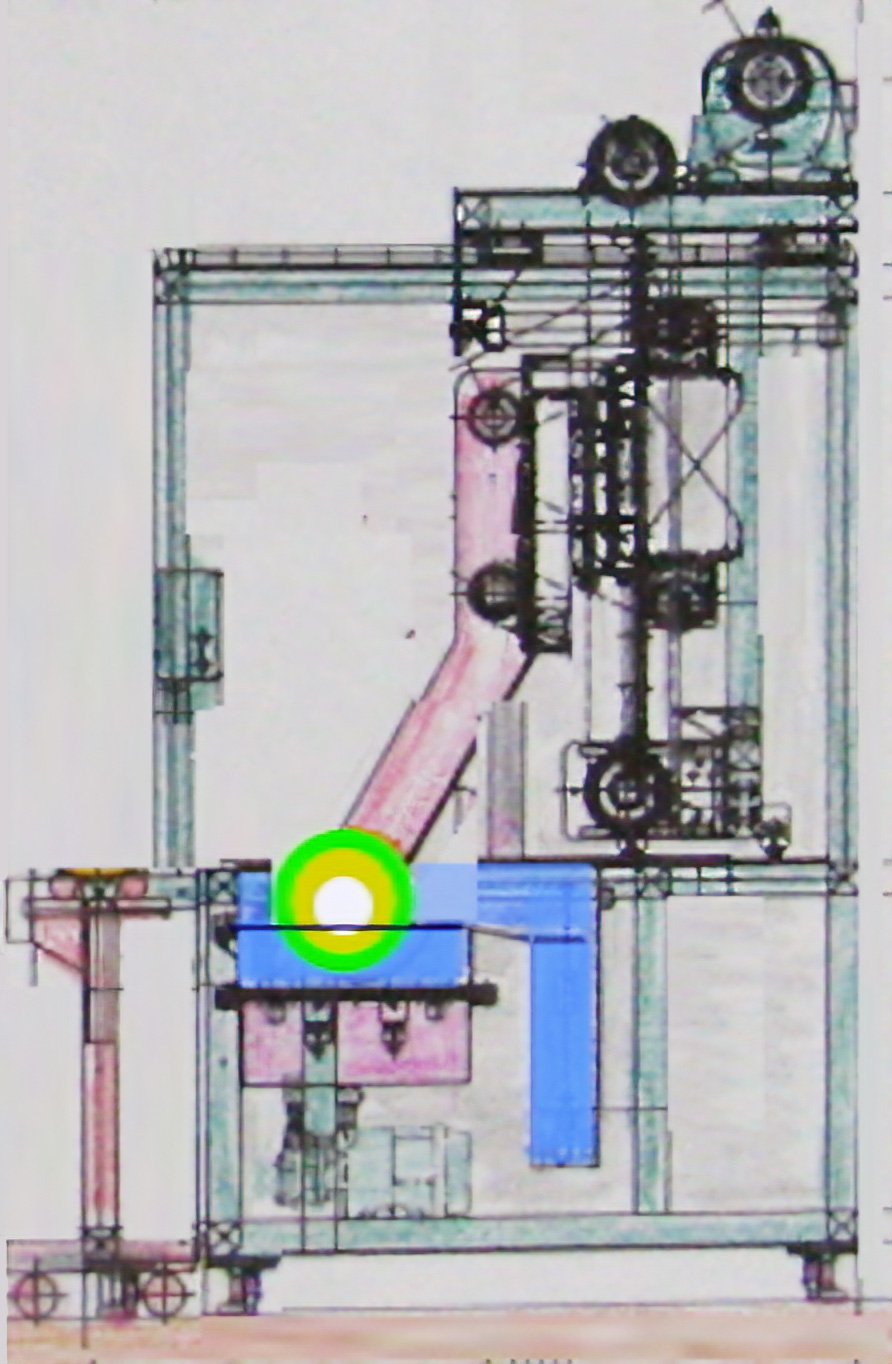

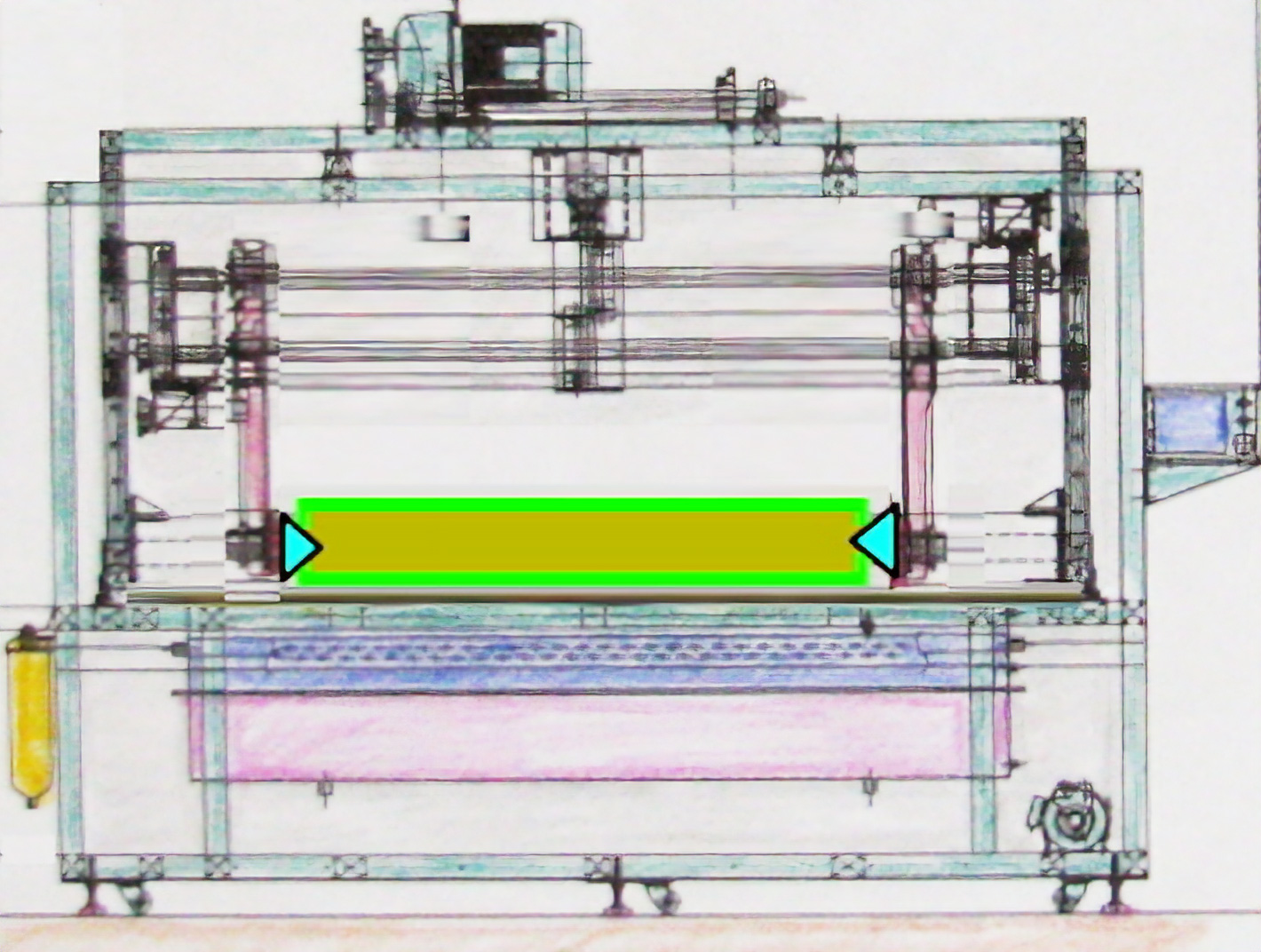

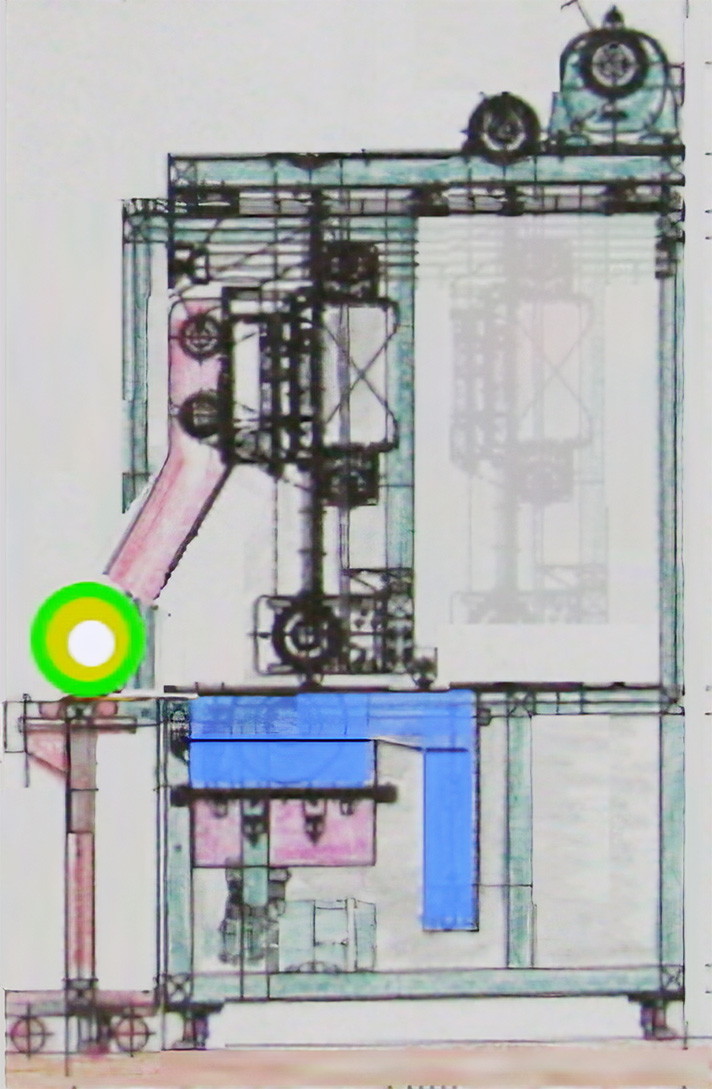

One-cycle, fully automatic gravure cylinder ultrasonic cleaning system

[Feature 1]Friendly to the working environment.No solvents are used.

Clean with a weak alkaline cleaner.Can be diluted or easily neutralised.No risk of ignition.No odour.Safe to use.*Blue Star R&D’s exclusive water-based cleaning agent.

[Feature 2]Everything from chucking the cylinder to cleaning is automatic.

No more struggling to carry heavy objects or worrying about setting them in the wash tank.Simply bring the cylinder onto the tray, set it in position and press the automatic push-button.The chucking device automatically seals the cylinder’s shaft hole while chucking it into the cleaning tank.There, it automatically detects the liquid level until no cleaning agent enters through the keyway of the shaft hole, lowers itself and starts the rotary ultrasonic cleaning process.The timer completes the cleaning and rises!Stops at the top of the cleaning tank.Here it rotates slowly so that any residues of cleaning agent can be wiped off.

Next, the cylinder moves to the front.Here, wrap the protective cover around the cylinder.Once this is done, the cylinder is returned to the first tray and the chuck automatically returns to its home position.The customer simply moves the tray and takes it to a storage area, for example.

[Feature 3] Compact size The device can be mounted on a wall, taking up very little space.

Maintenance filters are on the left-hand side.The control and management touch panel is on the right-hand side. One-cycle automatic, but retains the excellent cleaning power features of our conventional gravure cylinder cleaning systems.Maintenance is mainly filter cleaning.The filters use our unique, easy-to-maintain sanitary one-touch fittings, so SUS filters are easy to clean.The touch panel provides a clear picture of the operating status of the machine.It is an easy-to-understand and safe control device.

| item | Standard Specifications |

|---|---|

| Applicable cylinder shape and size | Sleeve type, 127 to 230 dia. Face length 850mm~1,300mm Maximum weight 70kg |

| Surface to be cleaned | Cylindrical section (ultrasonic cleaning) End surface (brush cleaning/optional) |

| Setting of the cylinder into the device | Automatic(Can be chucked in small increments) Cylinder diameter change ⇒ Vertical manual adjustment of roller position Cylinder length change ⇒ Automatic chuck method |

| Cleaning time | Approx. 5 min.(Cleaning time varies depending on ink type, degree of adhesion, and leaving time.) |

| detergent | Alkaline water-soluble cleaning agents |

| External dimensions of equipment/Weight | W2400×D1,500×H2,000 1,300kg |

| Sonicator | SIRIUS-1200~3600W 1unit(25KHz~275KHz) Choice of output depending on paint |

| Cavitation system | Optiin/Vunit typeL×1unit vacuum pump 310W×1unit Options/ Vacuum control system×1unit vacuum pump 310W×1unit |

| Circulatory filter | Circulating pump 310W×1unit SUS100μfilter 20μWfilter×1unit |

| Rotary motor | [going up and down]Guard motor 1.5W×1unit(With inverter) [Rotation]Geared motor 0.2KW 1unit[With speed control] [backward or forward movement]Geared motor 0.2KW 1unit[With speed control] |

| Cylinder rotation speed | 3~5rpm |

| primary power supply | three phases 200V about15KWA |

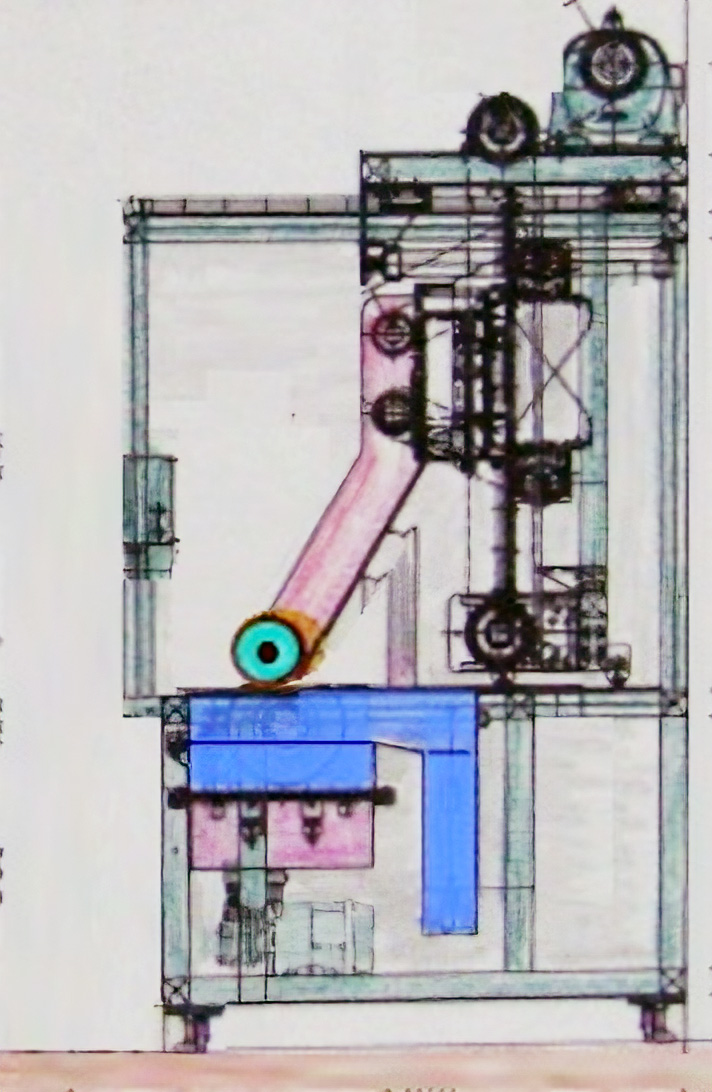

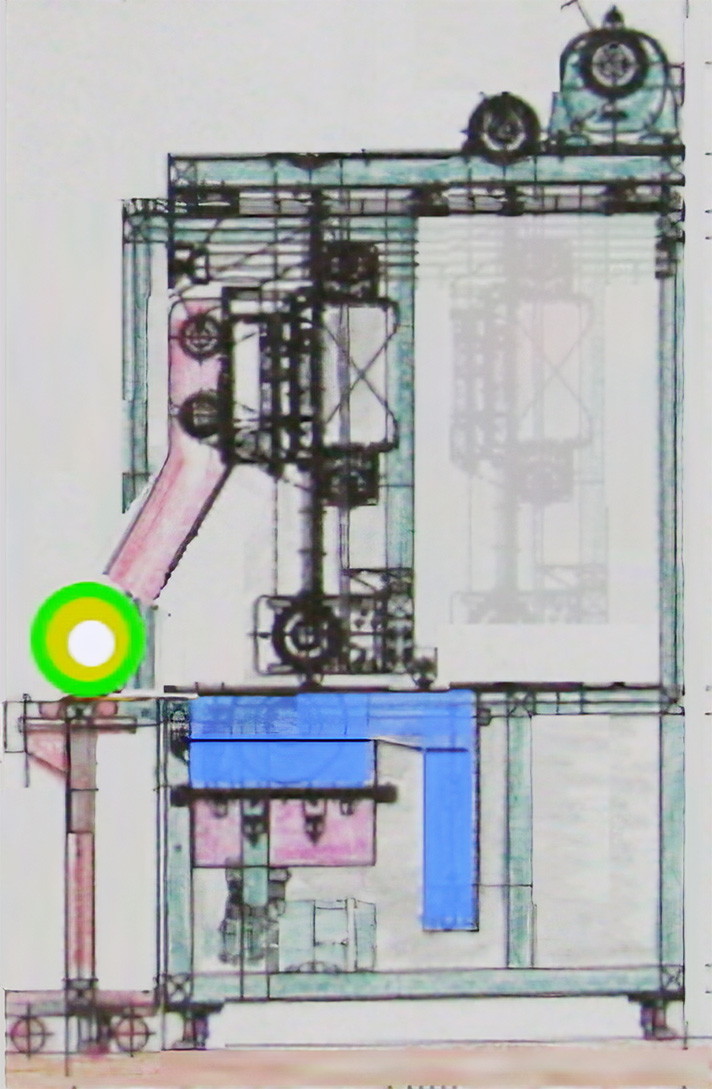

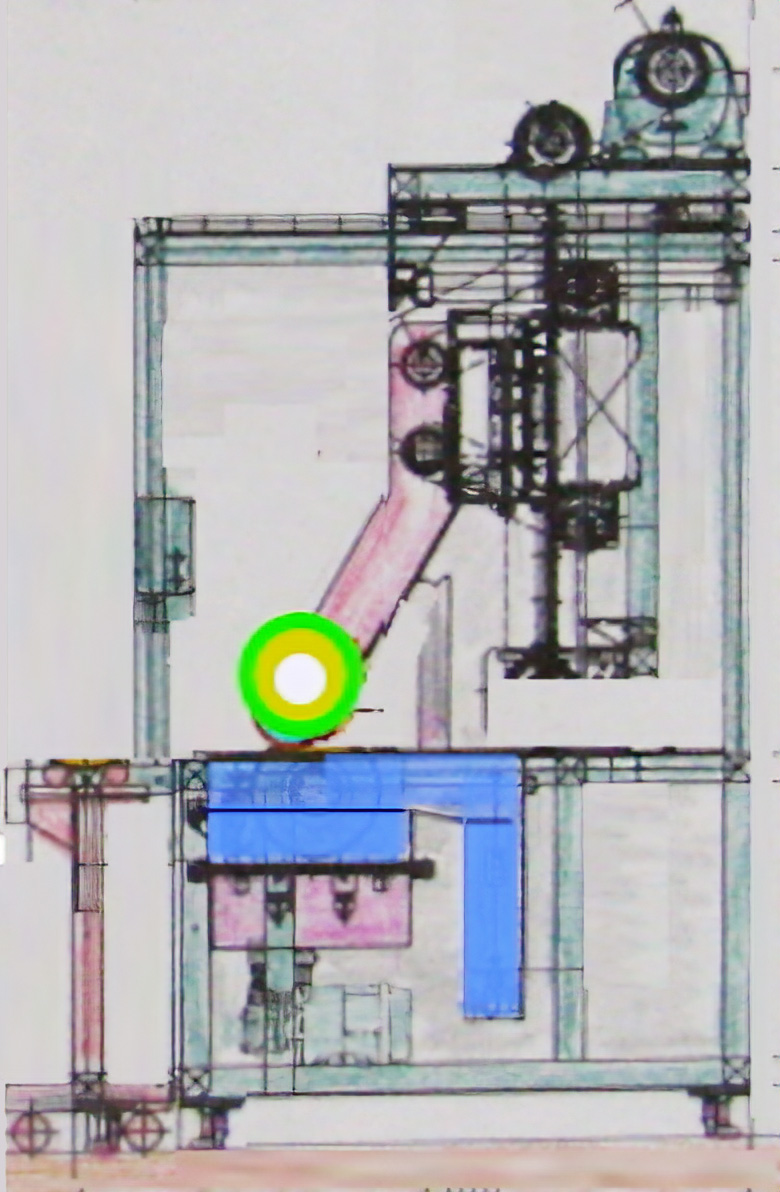

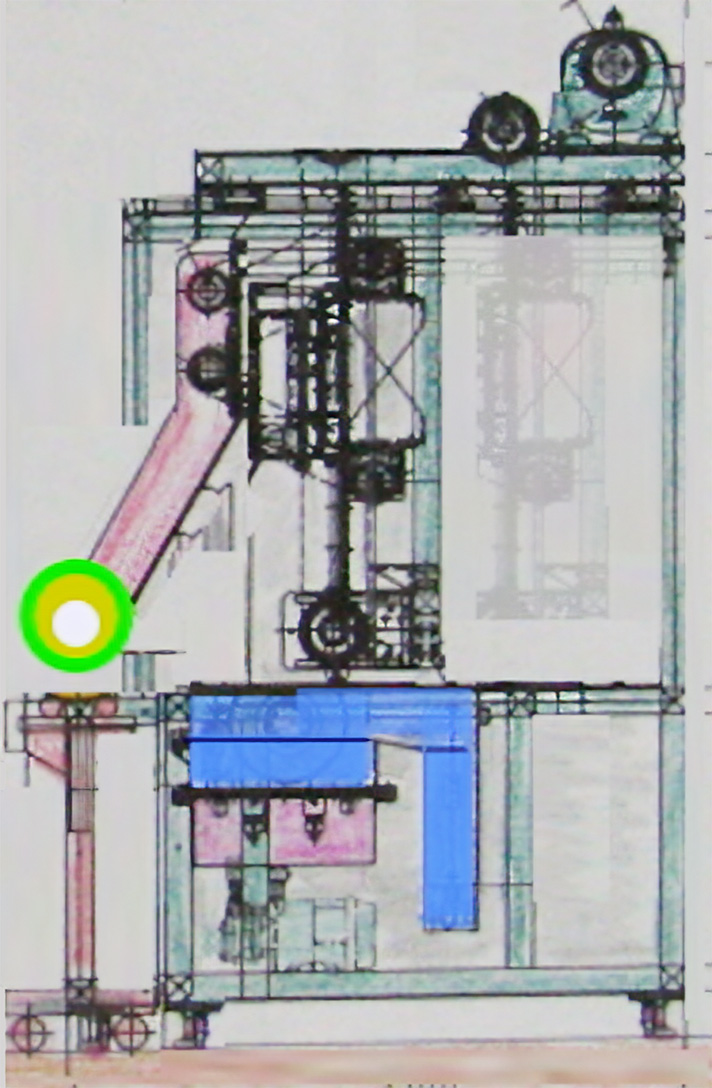

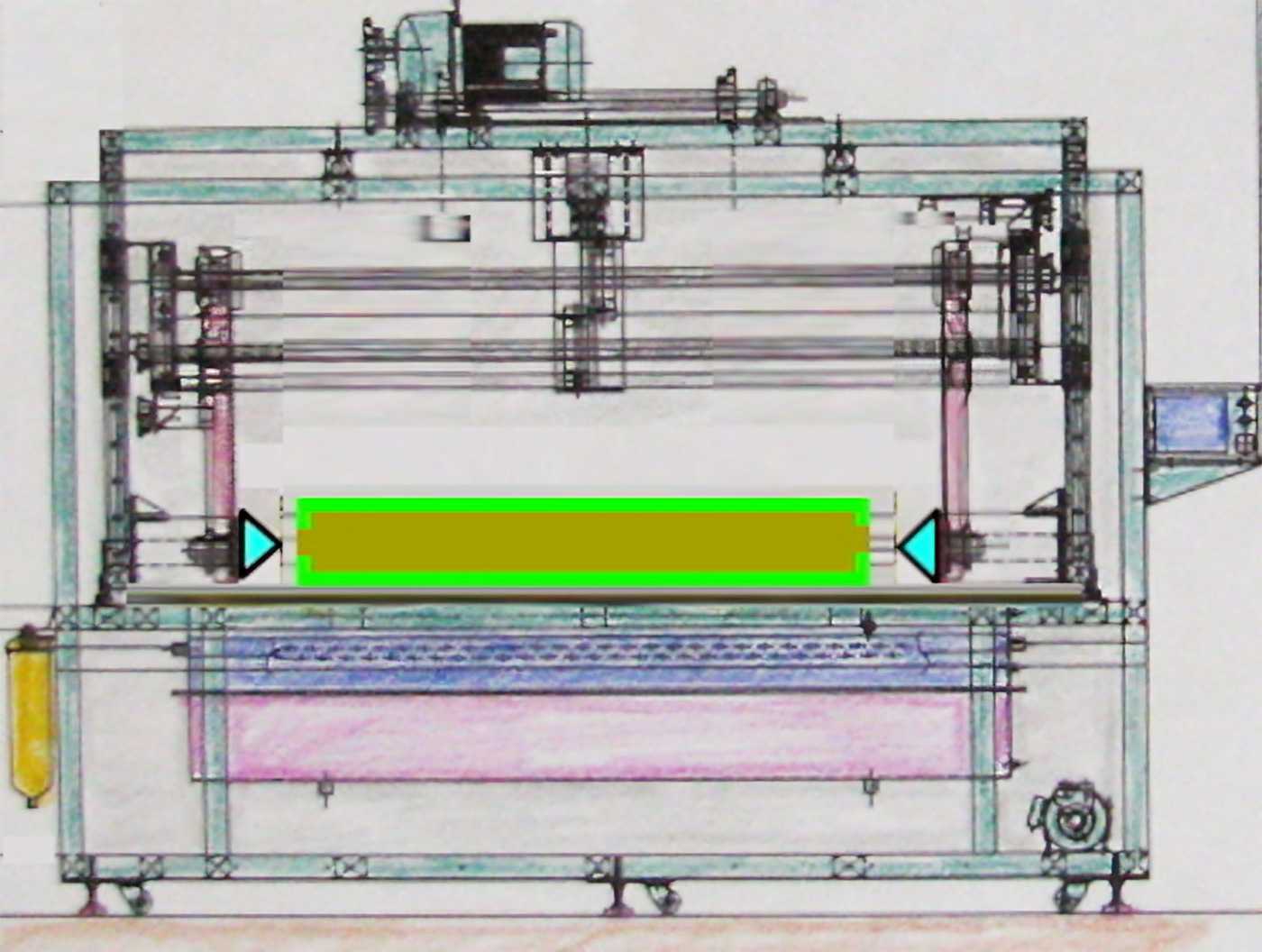

One-cycle automatic gravure cylinder cleaning machine Description of operating process

-

Standby stage

The cylinder is waiting to be assembled.

side view

front Drawing -

Cylinder arrival Combined

The dolly and the main body of the washer are automatically combined.

side view

front Drawing -

Cylinder Automatic chuck Fixed

Automatically chucks the cylinder shaft hole.At the same time, it also seals the cylinder to prevent liquids from entering.

side view

front Drawing -

Cylinder transfer movement

The gravure cylinder is transferred to just above the cleaning tank in the automatic chuck position.

side view

front Drawing -

Ultrasonic cleaning

Automatically determines the immersion depth of the gravure cylinder, descends and stops, rotates and performs powerful ultrasonic cleaning.The end faces can be brushed and ultrasonically cleaned.A circulation and filtration system is of course included.When the time set by the timer has elapsed, the machine finishes washing, rises and stops in position.

side view

front Drawing -

Intermediate stop Liquid spillage prevention

The machine stops just above the cleaning tank.Here, if necessary, it is slowly rotated backwards.Drain or wipe off the cleaning solution here.

side view

front Drawing -

Wrapping the protective sheet

To prevent damage to the gravure cylinder, a protective sheet is wrapped around it before it is placed on the trolley.Again, pressing PBSW will slowly rotate the cylinder backwards, allowing the protective sheet to be easily spread.

side view

front Drawing -

End

The gravure cylinder with the protective sheet wrapped around it is placed back on the trolley and the ultrasonic cleaner goes into standby mode.The carts are uncoupled and the gravure cylinders are moved to the warehouse.

side view

front Drawing

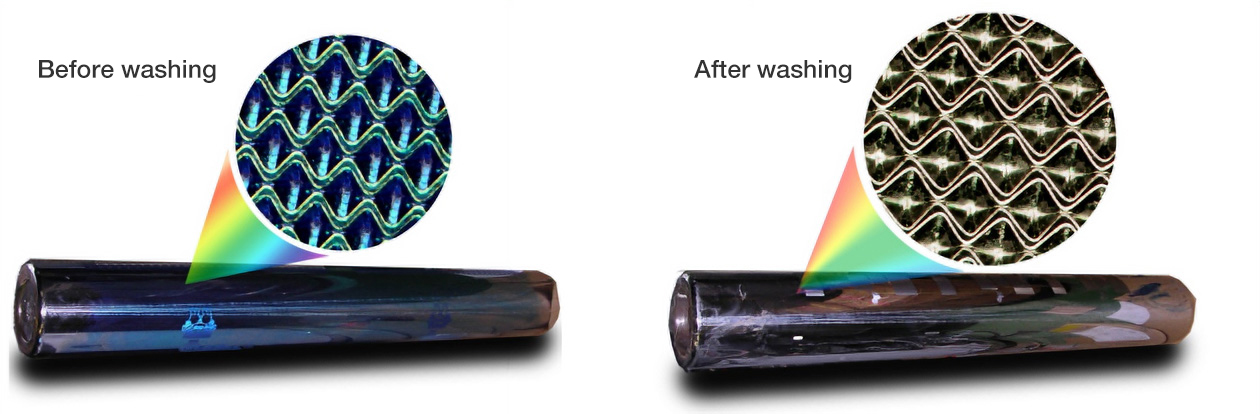

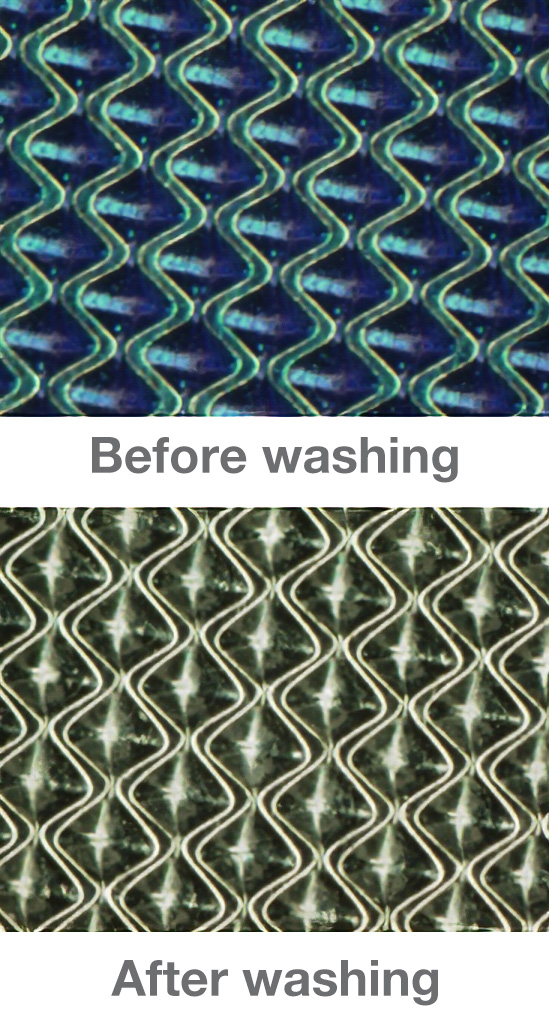

Before washing

Before washing After washing

After washingWe are a manufacturer of ultrasonic cleaning technology with the ability to control the positive and negative impact forces of ultrasonically generated cavities (microvacuum nuclei).There is no damage to your valuable cells.

Cleaning of rollers after lamination process.

- Save on reprint costs!

All customers have great difficulty in cleaning the rollers after the lamination process.Many customers re-plate after about two weeks of use.However, this is very expensive.And adhesives will continue to change towards faster curing speeds.

Therefore, we recommend a non-solvent, safe roller washer with a cavitation enhancement system, which offers the best performance for cleaning rollers after the lamination process.The basic form is the same as that of a standard gravure cylinder cleaner (see above).The difference is that the oxygen content in the cleaning agent is lowered to the limit and countless powerful cavities (groups of micro vacuum nuclei) are generated, which use their positive and negative impact forces to pull off and clean adhesives that are embedded and difficult to peel off.

Customers who have problems cleaning the rollers after lamination or are considering reducing the cost of re-plate processing are encouraged to contact us.

All rights reserved.