Blue Star R&D Co., Ltd

1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

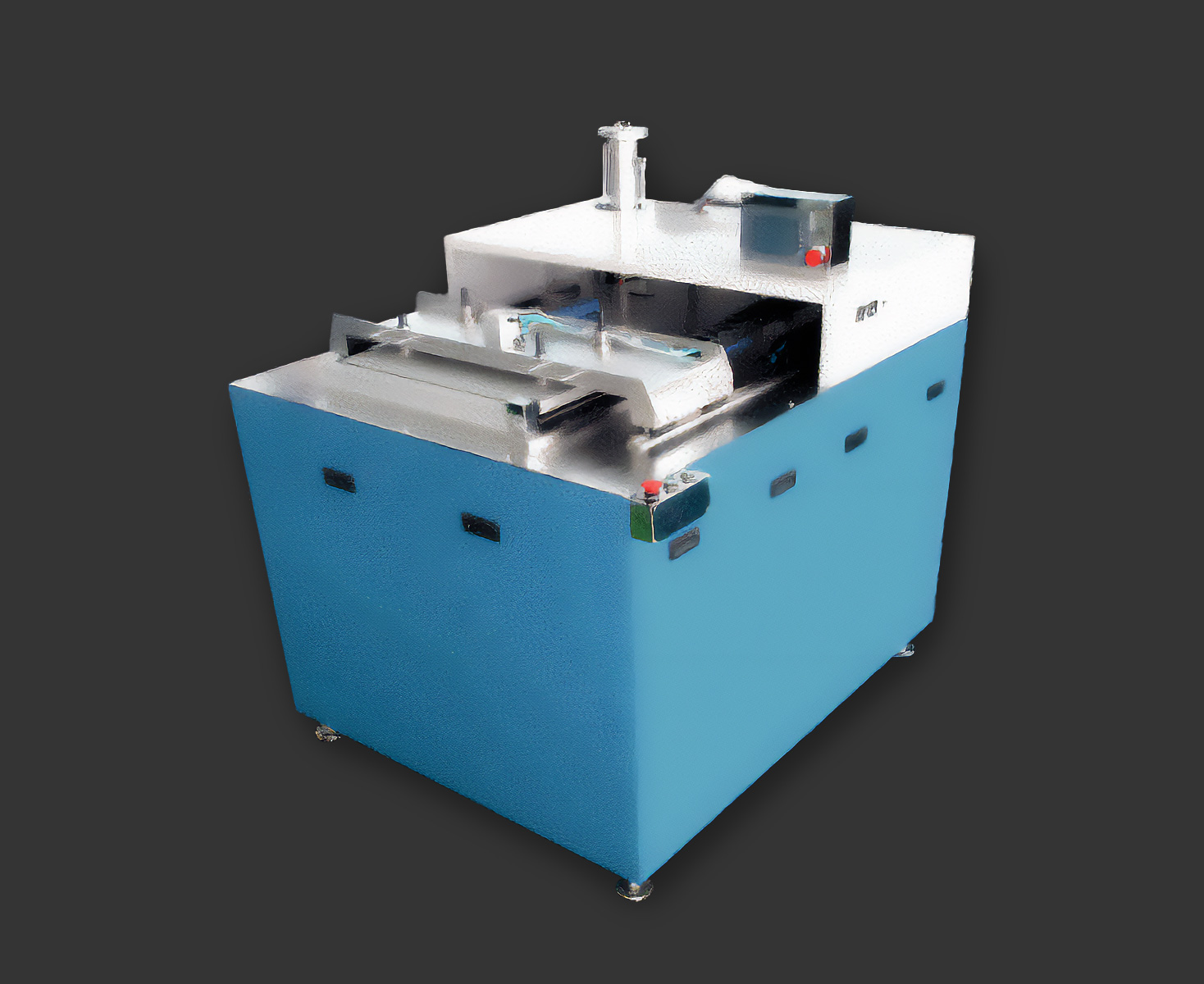

Vacuum pretreatment mold and ultrasonic casting sand removal system MARS-CSR

Eliminate misconceptions about ultrasonic cleaning and adopt true ultrasonic cleaning technology!

- Only a truly correct understanding of ultrasound can lead to dramatic cleaning effectiveness and consistent quality.

Vacuum pre-treatment mould with cavitation enhancement system Ultrasonic casting sand removal system MARS-CSR

Having undertaken ultrasonic complete casting sand removal for F1 engine blocks, oil pans, etc., the Company has put this technology to practical use as casting sand removal equipment for engine blocks of standard cars, etc., and has continued to deliver such equipment.This is a precision casting sand removal system after the casting sand has been removed to a certain extent by shot blasting, etc.Once the castings are vacuumed to remove any air remaining in the increasingly complex and precise hollows, powerful deburring ultrasonic waves are then applied to remove the casting sand that is embedded and stuck deep inside the casting, which is difficult to see with a scope.Ultrasonic casting sand removal is characterised by the fact that, compared with other methods, it can remove casting sand in hard-to-remove, invisible places, and is an environmentally friendly device with few consumables, easy to operate and safe to use.Of course, it also contributes to a reduction in manpower.Consider the many proven ultrasonic casting sand removal systems.

basic specification

| Properties of stains | Removal of casting sand from cast iron, aluminium alloys and copper alloys. | ||

|---|---|---|---|

| Ultrasonic frequency | 25KHz~275KHz | Ultrasonic force | 2400W~14400W |

| washing-up liquid | City water (cast iron may contain rust inhibitors) | ||

specification

| Item | MARS-CSR-2400×2 | MARS-CSR-3600×2 | MARS-CSR-4800×2 | ||

| Basket shape (internal dimensions) |

Width | 400mm | 500mm | 600mm | |

| Depth | 200mm | 260mm | 300mm | ||

| Hight | 300mm | 360mm | 400mm | ||

| main body | Equipment shape | Width (main body only) | 1400mm | 1600mm | 1720mm |

| Width (including filter and SWBOX) | 1396mm | 1596mm | 1716mm | ||

| Depth | 1400mm | 1500mm | 1600mm | ||

| Height | 1555mm | 1655mm | 1755mm | ||

| Siglal Tower | 1650mm | 1650mm | 1650mm | ||

| working height | 1225mm | 1275mm | 1325mm | ||

| Ultrasonic Slot Shape | Width | 540mm | 660mm | 750mm | |

| Depth | 390mm | 450mm | 510mm | ||

| Depth | 460mm | 520mm | 560mm | ||

| Liquid Depth | 360mm | 420mm | 460mm | ||

| Reservoir Shape | Width | 540mm | 660mm | 750mm | |

| Depth | 100mm | 125mm | 150mm | ||

| Depth | 400mm | 400mm | 400mm | ||

| Liquid Depth | 120ℓ | 170ℓ | 230ℓ | ||

| Weight | vacuity | 420Kg | 650Kg | 750kg | |

| euphasiid (any species in the family Euphausiacea) |

540Kg | 820Kg | 980Kg | ||

| Ultrasound | Oscillator SIRIUS-SuperMulti | 25~275KHz 1φ200V 2400W×2 |

25~275KHz 1φ200V 3600W×2 |

25~275KHz 1φ200V 4800W×2 |

|

| 振SIRIUS-SuperMulti Oscillator | 25~275Hz 1W/cm2 2400W×2 |

25~275KHz 1W/cm2 3600W×2 |

25~275KHz 1W/cm2 4800W×2 |

||

| Ancillary Equipment | Vacuum pumps for tank vacuum, vacuum pumps for degassing, vacuum deaeration towers, circulation filters, heat exchangers (chiller separately installed) – Equipment for up-and-down far movement – Others | ||||

| Power | Electricity | 3φ200V 10KW | 3φ200V 15KW | 3φ200V 19KW | |

The picture on the right shows a MARS-CSR-14400 ultrasonic system for removing casting sand from car engines.Two engine blocks are treated simultaneously.

All rights reserved.