1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

True ultrasonic cleaning system(water-based)

Eliminate misconceptions about ultrasonic cleaning and adopt true ultrasonic cleaning technology!

- Superior cleaning performance comes from a sound understanding of ultrasonic cleaning technology.

Please read → Japan: The Loss and Revival of Ultrasonic Cleaning Technology

True ultrasonic cleaning technology

Environmental issues and ultrasonic cleaning Misconceptions of ultrasonic cleaning (basic errors in cleaning principles!)How to choose the right ultrasonic cleaning liquid The correct meaning of the Cavitation Enhancement System Ultrasonic cleaning and tank geometry, etc.

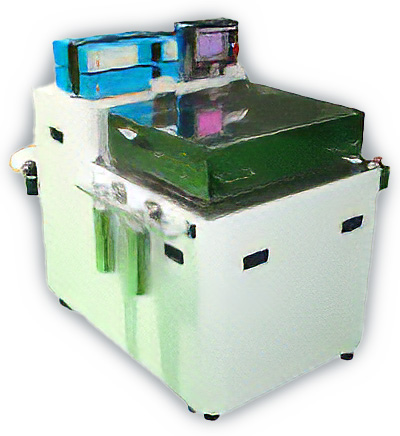

Powerful, ultrasonic cleaning device with cavitation enhancement system PERION-EH

General-purpose powerful ultrasonic cleaning device with up-and-down far motion device with vacuum continuous degassing device.

With filtration and vacuum equipment.Cavitation control tank.With horizontal opening and closing shutters.

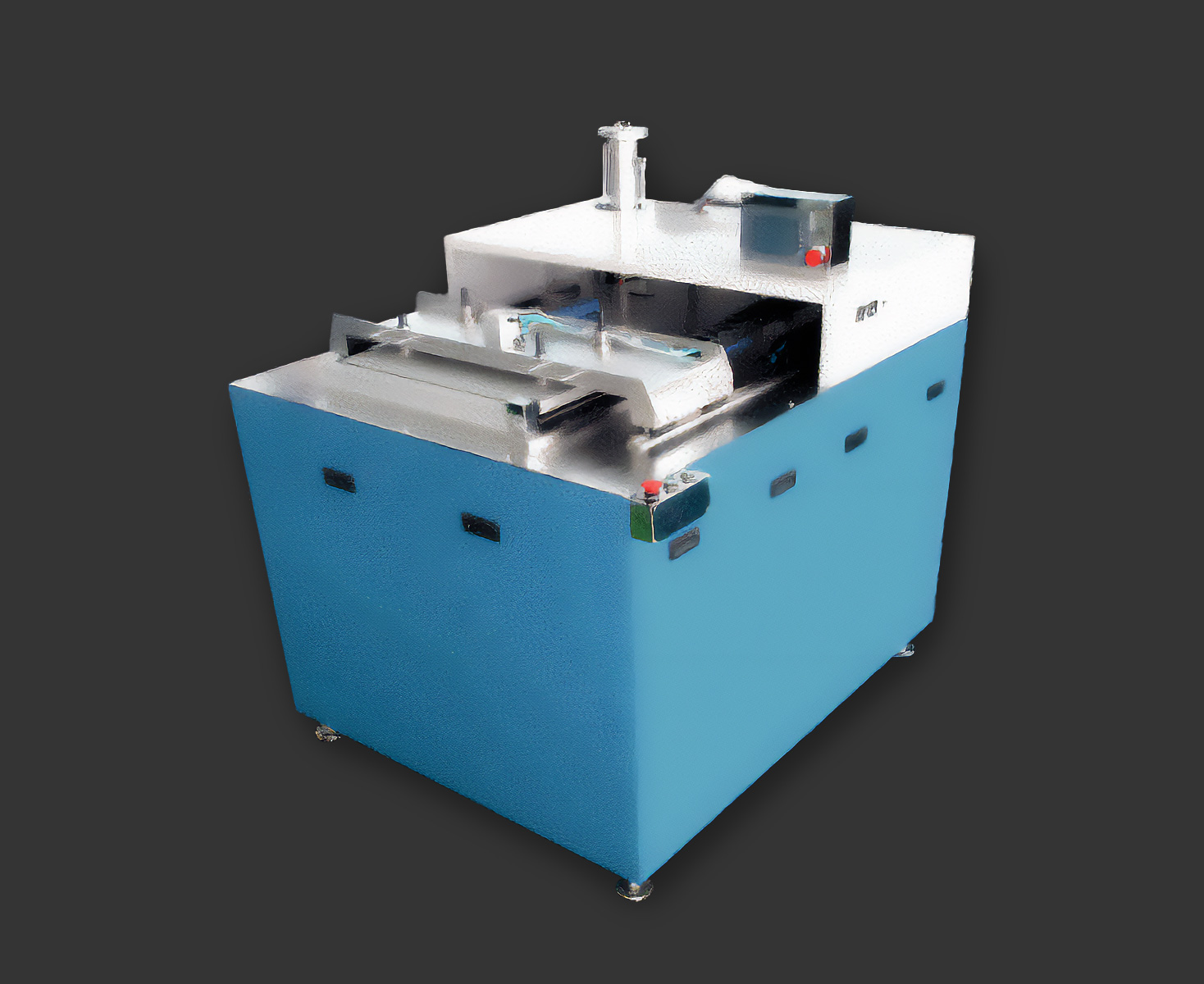

Vacuum-type, powerful ultrasonic cleaning system with cavitation enhancement system MARS-EH

For precision cleaning of objects that cannot be evacuated by air, such as stop holes, micropores, etc.

The object to be cleaned is placed in a vacuum, the air is removed, and then cleaned with powerful cavities (microspherical vacuum nuclei).

Various types of vacuum equipment 1 set, with filtration system, with vertical and horizontal shutters.

Versatile, fully automatic ultrasonic cleaning system with cavitation enhancement system VEGA-EH

Multipurpose ultrasonic cleaning and drying unit with powerful and dense ultrasonic cleaning and drying; 4-9 tanks.

With inlet/outlet conveyor.

Vacuum ultrasonic cleaning and vacuum drying selectable.

Frequency 25 KHz to 535 KHz, 50 KHz to 535 KHz selectable.

Specialised ultrasonic cleaning equipment with cavitation enhancement system e.g.

Gravure cylinders Powerful ultrasonic cleaning equipment Manual and one-cycle automatic (automatic chucking) Fully automatic and various types of powerful high-speed cleaning (water-based)

LCD APR Plate Precision Ultrasonic Cleaning System with Cavitation Enhancement System.

Compact – 4th, 6th and 8th generation 1-6 tanks.NMP and water cleaning, world’s first developer, many deliveries abroad.Ultrasonic 2400 W to 9600 W. 50-535 KHz specifications.

Brominated ultrasonic cleaning systems

Powerful ultrasonic cleaning equipment and deburring equipment using various liquids other than water-based and hydrocarbon-based liquids, such as bromine-based liquids, are manufactured.

If you have no choice but to use a solvent-based system, please contact us.

Basics of maintenance of ultrasonic cleaning equipment

- Ultrasonic cleaning equipment and installation environment.

- Daily inspection of ultrasonic cleaning equipment.

- Periodic inspection of ultrasonic cleaning equipment.

- Running costs and permanent equipment for ultrasonic cleaning equipment.

- For ultrasonic cleaning (solvent-based), click here.

- Photo-cleaning (UV/O3) click here.

All rights reserved.