1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

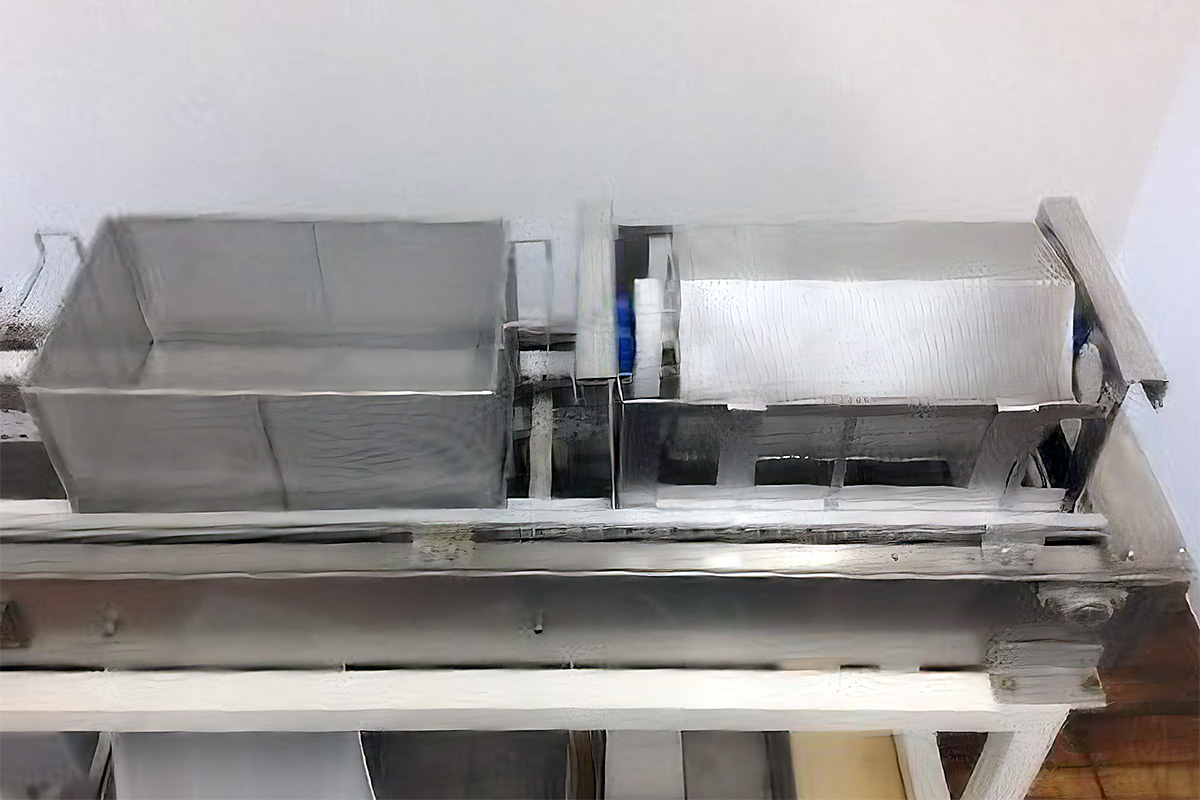

General-purpose, fully automatic ultrasonic deburring, cleaning and drying system, basket-rotating type VEGA-DBR

Reduced labour costs Stable quality Enhanced competitiveness

- Square cages and hexagonal rotating baskets for high-mix, precision manufacturing and fully automatic ultrasonic deburring and cleaning equipment.

Fully automatic, ultrasonic deburring and cleaning systems (4-6 tanks) are contributing to the quality control of our customers by further expanding our track record both domestically and internationally.In addition to water-based systems, hydrocarbon-based systems are also increasing. One of these customers is a customer who uses the machine to deburr and clean rolling taps used in precision small motors.We were informed of the need for an automatic deburring/cleaning machine that could handle both square and rotary baskets in a random manner with a single machine, as well as ultrasonic deburring/cleaning in square baskets. As a result of continued study and development, we developed and delivered an ultrasonic deburring/cleaning machine that can process both square cages and rotary cages randomly and automatically without changing the basics of the VEGA-DB series, which has been used stably for some time.This machine will be marketed and sold as a new member of the VEGA series.

Random use of square and rotating baskets is possible.

For deburring and precision cleaning.The latest results have shown that the deburring and surface polishing effects are superior to those of barrel polishing. This frees the customer from the hard labour of barrel polishing.

The basic specifications are the same as for the VEGA-DB series.

Basic Sspecification

| Properties of stains | Burrs during grinding, pressing and moulding processes(metal, plastic and composite materials) | ||

|---|---|---|---|

| Ultrasonic frequency | 20KHz~275KHz | For powerful deburring cleaning | General cleaning objects |

| 25Hz~275KHz | For deburring and cleaning | General cleaning objects | |

| washing-up liquid |

Pure water and city water *Hydrocarbon solvents are TypeS(safety-enhanced explosion-proof). |

||

| (data) item | VEGA-DBR-L-■ | VEGA-DBR-LL-■ | MARS-DBR-3L-■ | ||

| ultrasound | 2400W | 3600W | 4800W | ||

| Basket shape (internal dimensions) |

width | 400mm | 500mm | 600mm | |

| depth | 300mm(280Φ) | 360mm(340Φ) | 400mm(380Φ) | ||

| height | 100~150mm | 100~150mm | 100~150mm | ||

Standard Engineering

Entrance

Conveyor

Conveyor types

- Conveyor direction Parallel and perpendicular

- Dry conveyors Submerged conveyors

- 90-degree reversing conveyor

- 1~10m

Ultrasonic

Cleaning

Various ultrasonic cleaning tank specifications

- Tank process Ultrasonic 1-2 tanks

- Cavitation enhancement system (vacuum deaeration system)

- Vacuum pre-treatment ultrasonic tank

- Circulation filter 0.2-50 μ

- Superheater 3-10 KW

- Ultrasonic transducer output density 1W/cm2 2W/cm2

- Vertical far movement and basket rotation R

- Ultrasonic mounting position Bottom, side, both sides and top

- Other

Ultrasonic

Deburring

Various ultrasonic deburring tank specifications

- Slot work Ultrasonic 1 to 3 slots

- Cavitation enhancement systems (vacuum degassing systems)

- Vacuum pre-treatment ultrasonic tank

- Circulation filter 0.2-50 µ

- Vertical far movement and basket rotation R

- Ultrasonic mounting position Bottom, side, both sides and top

- Other

Dryness

Type of drying method

- Warm air blow

- Horizontal telemetry.

- Vacuum drying

- Suction drying and basket rotation R

Exit

conveyor

Conveyor types

- Conveyor direction Parallel and perpendicular

- Hooded conveyors

- 90° reversing conveyors

- Return conveyors

- 1-10 m

All rights reserved.