1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

Current status of ultrasonic precision deburring of plastics.

Plastic precision moulding is a battle against burrs!

- Customers who have tried everything – barrels, shots, etc.

- For plastic deburring, try ultrasonic deburring cleaning.

Following the practical application of a system for removing foil burrs in the in-mould moulding of mobile phones, DVDs, etc., the Company has developed a deburring and cleaning system for precision plastic injection moulding, and has built up a track record of orders received. Recently, there has been a sharp increase in requests for deburring after PPS moulding, and we have been busy with experiments and the resulting orders.

In the midst of this rapid economic downturn, we not only sell equipment, but also undertake commissioned ultrasonic deburring and cleaning work for customers whose production volumes are not stable or who have not yet received enough orders to purchase the equipment. We are now in the process of transforming ourselves from a manufacturer of powerful ultrasonic cleaning equipment into an ultrasonic deburring manufacturer that performs a wide range of ultrasonic deburring operations, from various metals and composite materials to plastic deburring. This paper summarises the current status of plastic ultrasonic deburring and its principles.

Current status of precision plastic deburring

It is no exaggeration to say that precision molding of plastics is a battle against burrs. The reality is that many parts of the burr removal process are still not automated and rely on manual labor. However, even in China, where labor costs are relatively low, rising labor costs are inevitable, and many customers in Shenzhen and Dongyan are unable to recruit personnel for deburring, which is having an impact on their operations.

Burr removal work, which is nerve-wracking but does not improve skills, is also a cause of dislike. The days of relying on cheap labor to remove burrs are coming to an end.

For example, at the Tianjin factory of a Taiwanese manufacturer that mainly manufactures cell phones and employs 1 million workers worldwide, 80% of the workers are said to be burr removers.

The other day, a newspaper reported that the management of the largest foreign company in China deteriorated immediately after the collapse of Lehman Brothers, and the Chinese government offered massive support to prevent political instability. (The Chinese government is currently recovering more than it was before the Lehman Shock.) From my experience of inspecting the line after the lecture at the factory in Shenzhen, I was concerned that quality control, as typified by deburring, was still dependent on cheap labor, and that this would further worsen the yield rate amidst the development of precision machining.

It is not unusual to see more than 100 people behind multiple injection molding machines! behind multiple injection molding machines is not uncommon.

Even in China, rising labor costs are inevitable.

In-mold printing, which simultaneously performs plastic injection molding and printing, is a breakthrough in eliminating the painting process from the production line, improving the environment, shortening the process, and providing beautifully printed products. However, the foil used for printing produced burrs, which could only be removed by hand, requiring a large number of deburring personnel.

For this reason, cell phone molding and processing plants were built one after another in countries with low labor costs to reduce the labor cost of deburring. Hungary and Brazil are examples.

However, this problem has been solved.

We have successfully developed and commercialized this foil deburring and cleaning system, and have continued to deliver it to customers.

However, the majority of plastic precision moldings are not in the field of competing for surface beauty, such as cellular phones, and most of them are moldings that have problems with burrs on the surface of the metal mold. However, even in China, where labor costs are comparatively low, cost competition is progressing, and reliance on human labor means that quality control is unstable.

As precision processing advances, plastic molding is also becoming more and more precise. There are fewer and fewer ways to remove burrs, and the number of burrs that can be removed by human operators is decreasing.

The market for precision molded plastic parts is huge, far exceeding the market for in-mold molding. The deburring of PPS, in particular, has had to be done manually because of its high pourability and excellent chemical resistance. There has been a worldwide demand for a technology to remove the minute burrs that occur even with these precision molds.

We have finally succeeded in establishing and commercializing a technology for removing precision molding burrs and processing burrs of precision plastics such as PPS, and we are now actively accepting experiments, enhancing the manufacturing capacity of our equipment, and strengthening our sales.

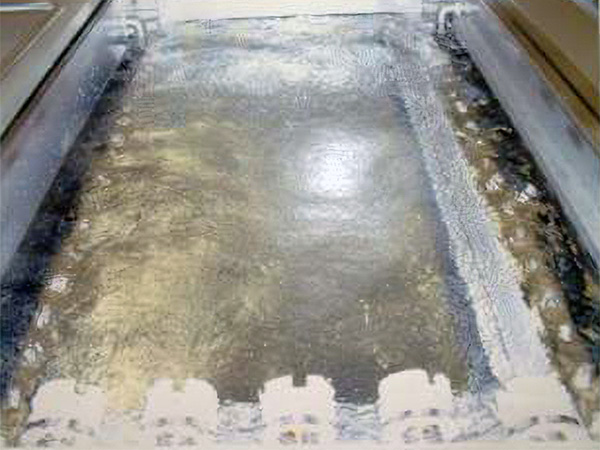

The basis of our deburring process is basically the same as ultrasonic cleaning, which involves placing a number of precision molded products in a basket, submerging them directly in water, and exposing them to powerful ultrasonic waves.

Since most precision plastic molded products do not release air when placed in water, a vacuum is created once and powerful ultrasonic waves are applied to remove burrs by the impact force generated when cavities made of spherical vacuum nuclei are generated and extinguished.

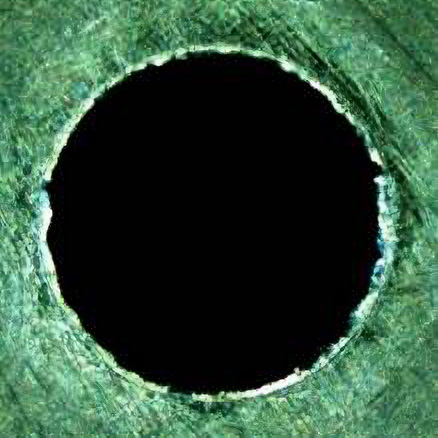

The removed burrs are quickly filtered out, so there is no risk of reattachment. Unlike our conventional ultrasonic removal of metal burrs, cavities that generate too strong an impact force cannot be used with plastics. They roughen, fluff, and in some cases puncture the plastic surface. Therefore, Star Cluster has developed a technology that consistently produces cavities that remove only burrs without damaging the plastic surface.

This technology can be applied to a wide variety of plastics.

Principle of ultrasonic deburring and cleaning

One example of fast-moving gases is gas explosions, but what moves fast during the creation and annihilation of microvacuum nuclei is a much denser liquid.The liquid moves at a speed of 50 to 100 metres per second (positive explosion) and then in the opposite direction at a speed of 50 to 150 metres per second (negative explosion).This is repeated more than 2000 times per second.Countless numbers of microvacuum nuclei are produced and annihilated synchronously.

The microvacuum nucleus group = cavity generated near the burr repeats on the burr, i.e. positive and negative impact forces, otherwise expressed as pushing and pulling, more than 2000 times per second.As a result, the micro burrs are instantly blown away.The burrs that are crushed and stuck to the body are subjected to more negative than positive, i.e. tensile, impact forces (some engineers still regard the mechanism of dirt removal by cavities as a unidirectional shock wave = micro-jet, which can only bite into the dirt).The dirt is gradually triggered and is destroyed (broken) and removed by similar repeated stresses.The rest of the process is similar to the precision cleaning process.

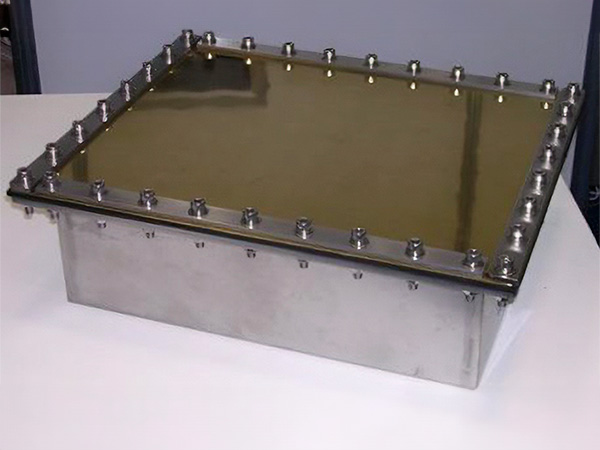

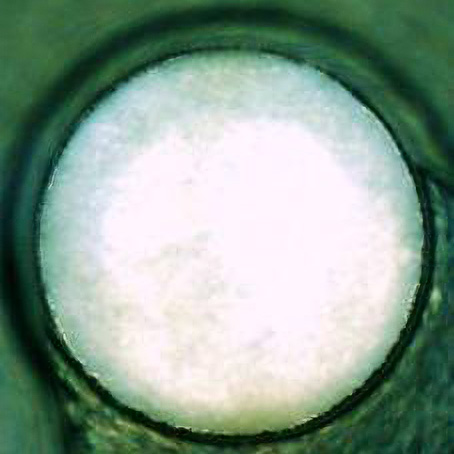

The key points of the ultrasonic deburring system are the ultrasonic transducer and the cleaning tank.The ultrasonic transducer continuously generates powerful cavities, so that the diaphragm itself is continuously subjected to violent impacts.For this reason, the surface of the transducer is coated with 50µ hard chrome plating and a titanium nitride coating (see picture).Otherwise, the diaphragm will be destroyed by the cavities within a few months.Even more easily overlooked are the cleaning tanks.Like the object to be deburred, the cleaning tank is also subjected to powerful cavity impacts.If subjected to a serious impact, even a cleaning tank made of SUS 304 3 mm can easily be destroyed from the welds.Therefore, it is necessary to design and manufacture safe ultrasonic cleaning tanks with precise cavity control to prevent shock waves and cavity concentration in the cleaning tank.

[’Points to bear in mind when carrying out ultrasonic deburring’.]

When performing ultrasonic deburring cleaning, the ultrasonic frequency and oscillation system should be changed according to the size of the burrs, the location where they are attached and the shape of the object to be cleaned.The size of the ultrasonic transducer is changed according to the size of the object.If the impact force of the ultrasonic waves is too strong, erosion may occur on the surface of the object to be treated, resulting in the destruction of the mirror surface and, depending on the object, the destruction of the product.For this reason, the following measures are taken.

Changing the frequency of ultrasound

- 25KHz to 275KHz Simultaneous multiple-wave wide-area oscillation Deburring of complex and solid shapes, PPS at this frequency

- 50KHz to 275KHZ Simultaneous multiple-wave wide-area oscillation Deburring of delicate components, electronic components, composite components

Screen with examples of ultrasonic deburring

Unfortunately, while there are over a thousand cases, they all belong to customers.We can only show you a limited number.

PPS ultrasonic deburring Pieces 100-500 at a time

Comparison with other means of ultrasonic deburring

Comparison with the main other deburring methods.

Ultrasonic deburring has many features not found elsewhere.

- Any material.Various plastics, metals, ceramics, glass and their composites.Basically, most materials can be used, although there are degrees of difficulty.Rubber is also gradually undergoing technological development.

- It is shape-independent, multi-directional where burrs occur, including tolerance holes on the inner surface.

- Not limited in number.From one to tens of thousands can be processed at once or in series.

- No hazardous substances, e.g. hazardous materials, are generated.Hazardous materials are not used.Use water.Hydrocarbon solvents if rust is a problem.Acids, alkalis and other solvents as required.Other solvents can also be used.

- Burrs can be removed while cleaning without contaminating the cleaned material.Precision cleaning is possible.

- No special technology or skills are required for use.Easy to automate.Easy to manage.

- The main advantage is that micro burrs (micron size) can be removed more quickly and reliably.This is the only means available for future precision machining.

- Even for delicate thin items [e.g. sheet materials] 50 µ or less in thickness, the technology has been solved by technical innovations.Masking technology is also important.

- Development of combined deburring technology is also in progress.Ultrasonic electrolytic deburring technology is also being developed.It can be shared with other existing means of deburring.

- Low consumables, e.g. filters.Small running costs.

- The cost of the equipment is a matter of sales strategy, as it is unique, but in any case, as a system it is far less expensive than other competing methods that require precision ultrasonic cleaning after deburring.

- Drying can also be done in line.Suitable for the treatment of precision parts processing air, as there is little re-adhesion of dirt.

- The above-mentioned advantages mean that they can be installed in environments such as cleanrooms, which do not require isolated deburring and cleaning rooms, as other measures do, and reduce administrative costs.

All rights reserved.