1-31-1 Yokoyamadai,

Chuo-ku, Sagamihara City,

Kanagawa pref. 2520241

- Cotnact

- +81-42-7117721

Ultrasonic deburring and cleaning system(water-based)

A revolution in deburring technology!

Ultrasonic deburring and cleaning technology!

Labor cost reduction

Quality stabilization

Competitiveness enhancement

History of the development of ultrasonic deburring cleaning 31 years (SHIBANO)

| 1985 | Developed and patented ultrasonic deburring/cleaning equipment [with double interface type cavitation enhancement system] using Furon-113 (CFC-113). Begins sales both domestically and internationally. |

|---|---|

| 1993 | Received the Stratospheric Ozone Protection Award and patent from the U.S. EPA for the development and popularization of ultrasonic cleaning of water cavitation enhancement systems (degassing systems) as an alternative to CFCs. |

| 1995 | Succeeded in developing a water-based ultrasonic deburring and cleaning system. Received the Medium and Small Business New Machine Development Award directly from Mr. Shoichiro Toyoda, Chairman of Toyota Motor Corporation at the time, for the successful development and commercialization of the ultrasonic deburring system. |

| 2008 | As a director of the Surface Treatment and Deburring Technology Research Association (BEST-JAPAN), successfully organized an international deburring conference at Suzhou University, Suzhou, China, co-sponsored by Dalian University of Technology, Taiyuan University and Suzhou University, with special permission from the Chinese government. (Resigned from BEST-JAPN shortly thereafter) |

| 2011 | Decided to develop and put into practical use the ultrasonic deburring and cleaning technology that fits the times. Realizing the limitations of deburring using conventional ultrasonic cleaning elements, the company began development of a dedicated deburring vibration element. The development was approved as a Kanagawa Prefecture Creative New Technology Development Plan. |

| 2012 | Received the Kanagawa Prefecture Block Machine Society Technology Award and succeeded in developing an ultrasonic vibration element exclusively for deburring (first product) and put it into practical use. |

| January 2013 | Succeeded in developing an ultrasonic transducer dedicated to deburring (2nd product), and is currently verifying durability, etc. Strengthening overseas sales development. |

Principle of ultrasonic deburring cleaning

Burrs are removed by repeated positive and negative impact forces during the creation and annihilation of spherical nebula cavities (microvacuum nuclei groups). Fatigue fracture…

Features of ultrasonic deburring cleaning

It has many features not found in conventional deburring techniques, but its greatest feature is that it can be used for deburring of any material. It is used to deburr a wide variety of materials, including metals, plastics, and composite materials. For more information on other features, please visit…

Ultrasonic Deburring Case Studies

Balanced experimental samples are very important to our customers. Many of them are directly related to our undisclosed precision processing technology. Therefore, we cannot disclose them to the public. We are pleased to present some of the samples that have been approved for release.

Please take a look. Different from conventional deburring technology without relying on manpower…

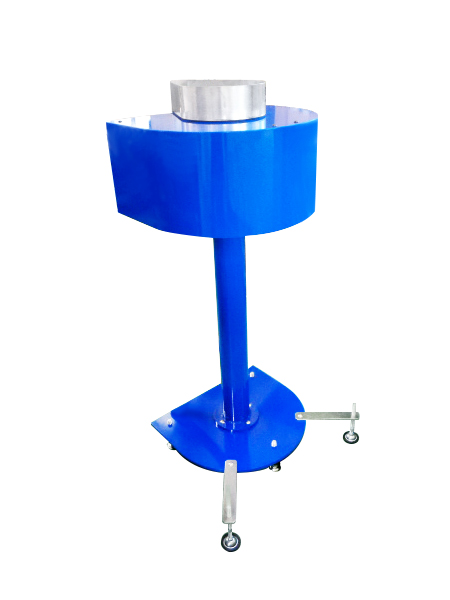

World’s first! Ultrasonic Deburring and Cleaning System BlueShock

Ultra compact! Ultra powerful!

Instantaneous deburring and cleaning

Ultimate ultrasonic technology

– No blind spots –

Simultaneous ultrasonic irradiation all around

– Ultrasonic density up to 450W/ℓ

– Single unit use

– Multiple units use

Compact ultrasonic deburring and cleaning system with cavitation enhancement system StarBaby-DB

Compact ultrasonic deburring/cleaning system.

For ultrasonic deburring and cleaning of small items.

Can be placed alongside the work desk for use.

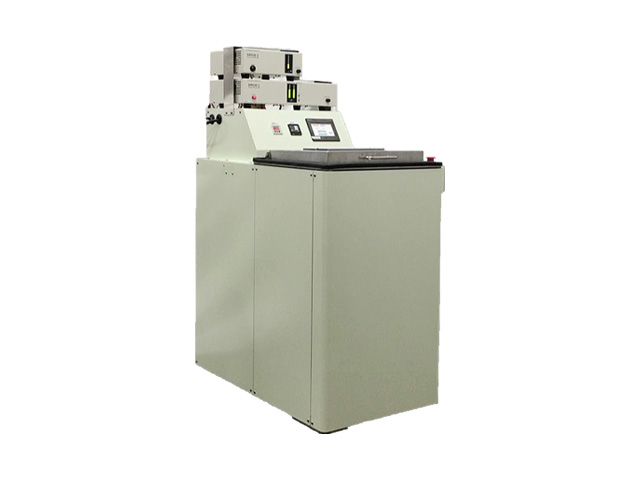

Ultrasonic deburring and cleaning system with cavitation enhancement system PERION-DB

General-purpose ultrasonic deburring/cleaning device

Most widely used standard deburring device.

With up-and-down motion device and continuous vacuum degassing device.

Equipped with filtration and vacuum equipment. Equipped with horizontal open/close shutter.

Vacuum type and ultrasonic deburring/cleaning system with cavitation enhancement system MARS-DB

For precision deburring cleaning of machined parts where air cannot escape, such as stop holes and microholes. The object to be cleaned is first placed in a vacuum to remove air, and then deburred by powerful cavities (micro spherical vacuum nuclei). This is a popular general-purpose machine with various types of vacuum equipment, filtration equipment, and vertical and horizontal shutters.

Multi-purpose Fully Automatic and Ultrasonic Deburring and Cleaning Equipment with Cavitation Enhancement System VEGA-DB

Patent pending

Multipurpose ultrasonic cleaning/drying unit with fully automatic ultrasonic deburring/cleaning. 3 to 5 tanks.

With inlet/outlet conveyor.

Vacuum type ultrasonic deburring/cleaning and vacuum drying available.

Selectable frequency 25KHz to 535KHz or 50KHz to 535KHz.

The definitive general-purpose automatic deburring/cleaning/drying machine.

Consumables for ultrasonic deburring and cleaning equipment

Many deburring machines sell the machine itself at a low price and make a profit on consumables. However, ultrasonic deburring machines have very few daily consumables: water, electricity, pneumatics, and filter filters. Ultrasonic vibration plates are available at…

Ultrasonic Deburring and Cleaning System Maintenance Basics

Ultrasonic deburring/cleaning equipment and installation environment

Daily inspection of ultrasonic deburring/cleaning equipment

Periodic inspection of ultrasonic deburring/cleaning equipment

Running cost and permanent equipment of ultrasonic deburring/cleaning equipment

Current Status of Ultrasonic Precision Deburring Cleaning of Plastics

Following the practical application of the foil deburring system for in-mold molding of cellular phones, DVDs, etc., we have developed a deburring cleaning system for precision plastic injection molding, and have been receiving orders for this system since then, accumulating a track record. Recently, requests for deburring after PPS molding have been rapidly increasing, and we have been busy with the experiments and the results of those experiments to respond to the orders.

In the midst of this rapid economic downturn, we not only sell equipment, but also provide contract ultrasonic deburring and cleaning services to customers who have unstable production or who have not yet received enough orders to purchase equipment. We are now in the process of transforming ourselves from a manufacturer of powerful ultrasonic cleaning equipment to a manufacturer of ultrasonic deburring equipment for a wide range of applications, from various metals and composite materials to plastic deburring. This paper summarizes the current status of plastic ultrasonic deburring and its principles.

vibration plates are available at…

Difference between existing deburring methods and ultrasonic deburring and cleaning technology

Click above to see the comparison chart.

Click here for ultrasonic deburring cleaning (solvent-based)

All rights reserved.